LaserCutter

| LaserCutter Release status: stable [box doku] | |

|---|---|

| Description | A Laser to cut stuff |

We bought a laser! This page should be used for documenting stuff.

Before starting, please read the Safety Guidelines

Here is THE Manual for using the Laser Cutter: Using the Laser Cutter

Features

- Big build area (Table Size: 1240 x 1000 mm / max Cutting Size: 1140 x 800 mm)

- Red light mode for dry run (could need a second laser source ) - In Progress

- 80W CO2 (see [1]), wavelength ≈ 10 microns

- AWC608 Controller (see [3])

Components / Parts

- Anywells AWC608 Laser Engraving Cutting Controller

- Reci 80W CO2 Laser Tube

- HY-T80 Laser PSU (http://www.jnhyec.com/en/productxx.asp?signid=90&proid=124}

- Step Up Converter LM2596S (maximum input voltage 35V)

Handover

Videos: https://www.flickr.com/gp/peterfroehlich/37Y0h0

Documentation: https://www.dropbox.com/sh/enh2fepkbfpnuyg/AAB81zYn4_yINY1aRJK2Tknsa?dl=0

Wiring diagram: http://www.lightobject.info/download/DSP/LaserMachineWiringDiagram2.jpg

LaserCAD: http://www.lightobject.info/viewtopic.php?f=55&t=2484

Knowledge

Laser saur manual (our cutter is NOT a laser saur, but there are some similarities: http://www.lasersaur.com/manual/

Awesome source of knowledge about diy laser cutters: http://www.buildlog.net/

Open Protect and water flow pins on controller / laser psu: http://www.lightobject.info/viewtopic.php?f=8&t=2015

Lasersaur Mailing list: https://groups.google.com/forum/#!forum/lasersaur

Introduction to CO2 lasers (read the safety part!) http://www.repairfaq.org/sam/laserco2.htm

Controller pins:

- OUT1: Output "Low" when XY start to move. OK to use this output to control air-pump On or Off as "Air-pump" take time to pump air out and slow

- OUT2: Output "Low" when laser is firing:

- Note that there is no output when XY is moving. It is ideal to use it to control an air-valve when use "Air compressor" as air-assist. Faster action

- Use the same output to trigger a timer/counter for counting laser usage.

- IN1: Door open protect (pulled to GND is closed)

- Other I/O are "NA" and reserved for future expansion

- Warning: TTL is 24V! Still, OUT1/2 are not powerful enough to drive a classical relais.

Calibration

Safety warning: For calibration it is necessary to deactivate the sensors of the hatch. Therefore, wearing safety glasses is absolutely mandatory. Do not calibrate the laser with persons without safety glasses in the space.

Calibration works well using sticky notes attached to the mirror mounts. Laser output is to be set to 20%. The laser is then fired manually (1-3 seconds) until a burn pattern becomes visible on the sticky note. There were always two burn marks when we were calibrating (Why?). The first calibration was done starting with the mirror next to the laser tube, then working the way toward the cutting area.

- The laser spot is not circular: Most probable cause is the mirror directly above the lens.

Links::

http://wiki.fablab-karlsruhe.de/doku.php?id=maschinen:lasercutter:wartung:kalibration

ToDo

wire up electronics and HAL sensor<done>Review power circuitry<done>Install FlowSensor in Chiller(was already installed)Learn serial protocol of Chiller(Adrian) There is no serial :/Complete outer case (to avoid escaping beam)Complete inner case (to avoid escaping exhaust gases)(Ricardo)Build exhaust venting systemInstall gas cylinders to prop up hood (see [4] for choosing correct cylinders)(Eymen) <done>insert optical componentscalibrate optical components [6]connecting laser tubeinside illumination (white leds)write manual and documentation(Eymen)Control and safety panel- RFID-Access-System (Jorgen) <in progress>

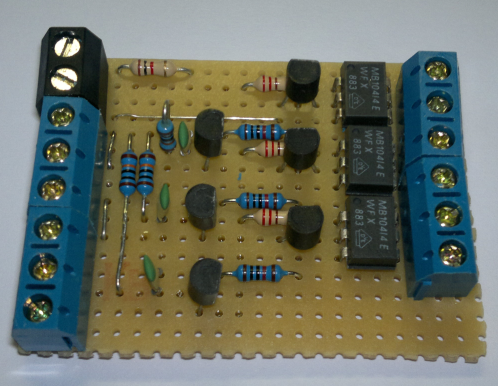

Safety System panel

Code on github

The Safety System runs on an Arduino, checks for

- Water flow (Right before the laser tube, arduino counting pulses)

- Chiller temp (measured before and after laser tube)

- Exhaust system (differetial pressure; digital)

- water leak under the chiller and in connection pipe on both sides (digital) (--> Heiko)

- lid closed (reed contacts, directly connected to the controller --> Peter)

--> Adrian, Heiko (Code review by Peter?)

Maybe later:

- Compressor running

- power consumption (???)

- ...

Sensors

Waterleak

Consumables

Our laser tube:

- Reci W3 80W Long life CO2

Mirrors:

- use copper-backed or molybdenum-backed mirrors. Do not use silicone backed mirrors.

Finance

When we have this thing running, we maybe need to think how we can get the costs back in. A 100W laser tube costs around 1200€ and has a lifetime of 6000-10000h.

As discussed on the 20150315 Plenum (and again in 20161009 Plenum), we will start with the following structure:

- 2€ per 10min for members, 3€ for HuS, 4€ for non-members, 5+€ for "commercial" use

Logging

We installed a data logger to keep track of the usage hours. The logger tracks the time the air assist is on, which is just about the runtime the laser controller displays for a job. We want to use this to track the working hours of the laser tube, but if you want to check how long your laser cutting jobs took, feel free to checkt that here as well:

Inspiration

Some connectors: - https://www.flickr.com/photos/satiredun/15868308421/sizes/o/ 'PCB' out of steel: - https://www.youtube.com/watch?v=OtZQoIheYcc

Additional Parts

- Gas spring, Price 24€, Manufacturer Shockex, Part number 1181202100, Amazon [5], Force: 320 N, Outer diameter 1: 18 mm, outer diameter 2: 8 mm, Stroke length: 187 mm, Lenght: 468 mm

Sources

- [1]: http://support.epiloglaser.com/article/8205/42827/

- [2]: http://www.lasersaur.com/

- [3]: http://www.lightobject.com/AWC608-Commercial-DSP-CO2-Laser-Engraving-Cutter-Controller-P321.aspx

- [4]: http://www.gasfedershop.de/gasfeder_berechnung/

- [5]: http://www.amazon.de/gp/product/B008MPR8W8

- [6]: https://www.youtube.com/watch?v=Wpsi3tKJGMo