LaserCutter/Technical Details

Laser Tube

Reci CO2 Laser Tube 80W (Peak 100W) 1240mm W2 / S2 und DY13

Air extraction system

Filter: Two cubes of "bag filters" are used. Filter class G4 (DIN EN779) and Filter class F7 (DIN EN779).

Both cubes have the dimensions: 592 x 592 x 360 mm

Example filter:

| Top | Taschenfilter Güteklasse G4 nach DIN EN779

Taschenfilter synthetik Güteklasse G4 nach DIN EN779 ISO 16890 Coarse 60% 592 x 592 x 360 mm 6 Einzeltaschen 25 mm Stahlblech, verzinkt |

| Botton | Taschenfilter Güteklasse F7 nach DIN EN779

Taschenfilter synthetik Güteklasse F7 ISO 16890 ePM2,5 65% 592 x 592 x 360 mm 8 Einzeltaschen 25 mm Stahlrahmen, verzinkt |

ToDo: Put more information about the air extraction system here.

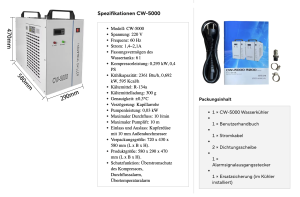

Cooling

Demineralised water.

ToDo: Put more information about the cooling system here.

Laser Controller

Our laser controller is a Trocen AWC7813 (until 11.2025 Trocen AWC7824). The manual is located at File:AWC7824 user manual RV1.3C .pdf

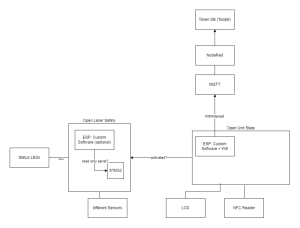

Laser Safety System

Overview (01/2026)

Token System

The token system is based on OpenUnitState

- The MQTT, NodeRed is still hosted by an former member. Tooljet itself is a SaaS offering.

- OpenUnitState is integrated to the Laser Safety System just as input and can be bridged in case of issues: https://github.com/homeofmaking/OpenLaserSafety/blob/main/Software/Core/Inc/config.h#L61

- The dependency on MQTT and the external backend is not optional and there might be better solutions in the mean while like: https://2log.io/

LaserSafety Unit

- Using OpenLaserSafety (v1.0 at the time of writing) designed by Home of Making e.V.

- Outputs a single master signal to the laser controller

- Signaling to an i2c LED board

- Board has an own STM32 microcontroller, program-able via ST-Link Programmer

- Logs can be fetched by a Wemos D1 Mini; The ESP is completely optional

Checks the following sensors:

- Pressure Sensor to check if the exhaust is on and filter not congested (Honeywell HSCMRRD002NDAA5). This sensor compares the pressure inside and outside the extraction system, and outputs a voltage between 0v and 5v. 2.5v is the midpoint when the extraction system isn't running. (1.4 is too low to activate, actual threshold unknown) https://4donline.ihs.com/images/VipMasterIC/IC/HWSC/HWSC-S-A0012826461/HWSC-S-A0012826924-1.pdf?hkey=CECEF36DEECDED6468708AAF2E19C0C6

| Color | Function | Pin |

|---|---|---|

| brown | Vsupply | 2 |

| yellow | Vout | 3 |

| white | Ground | 4 |

| NC | NC | 1,4-8 |

- Dip switch for an alternative exhaust check

- Flow & Water temp sensor (this one in 1/2")

- Lid status (separate for L/R sensor)

- Fire suppression system status (currently not in use)

- External machine unlock (currently not in use)

Sensor 'bus' cable to back: There is a big 12 wire core cable that runs from the safety board to the back of the laser, terminated on a screw terminal block.

| Color | Function | Pin on terminal block |

|---|---|---|

| brown | 5V | 1 |

| white | 3.3V | 2 |

| black | Ground | 3 |

| yellow | Pressure sensor | 4 |

| green | Exhaust flap | 5 |

| purple | Temperature sensor | 6 |

| grey | Flow sensor | 7 |

| blue | NC | 8 |

Sensor values: https://github.com/homeofmaking/OpenLaserSafety/blob/main/Software/Core/Inc/config.h#L14

Known issues:

- I2C connection to the LEDs is not super stable and is implemented with some workarounds: I2C very susceptible to interference, and the line here is already quite long. The bus is already set to 100 kHz, but it still needs a reset fallback because the bus occasionally goes out of sync: https://github.com/homeofmaking/OpenLaserSafety/blob/main/Software/Core/Src/tlc59116.c#L103

Mirrors

- Use copper-backed or molybdenum-backed mirrors. Do not use silicone backed mirrors.

- Cleaning process: to be documented

- Bought in 2025: 3x Molybdenum mirrors (Diameter: 25 mm) https://amzn.eu/d/huC1l4K

Logging

We installed a data logger to keep track of the usage hours. The logger tracks the time the air assist is on, just about the runtime the laser controller displays for a job. We want to use this to track the working hours of the laser tube, but if you want to check how long your laser cutting jobs took, feel free to check that here as well:

2025: Hour counter was removed since it wasn't in use for a long time.

Additional Parts

- Gas spring, Price 24€, Manufacturer Shockex, Part number 1181202100, Amazon, Force: 320 N, Outer diameter 1: 18 mm, outer diameter 2: 8 mm, Stroke length: 187 mm, Lenght: 468 mm

- LED-Streifen 12V Kaltweiß

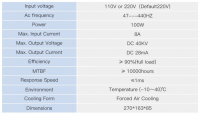

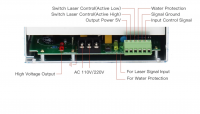

High voltage power supply

WaveTopSign HY-DY13 100W Co2 Laser Power Supply For RECI Find the manual here: File:HY-DY13 manual.pdf

Wiring

Pre 2022 maintenance wiring diagram

Out of date Laser Controller pinout (old controller)

Controller pins:

- OUT1: Output "Low" when XY start to move. OK to use this output to control air-pump On or Off as "Air-pump" take time to pump air out and slow

- OUT2: Output "Low" when laser is firing:

- Note that there is no output when XY is moving. It is ideal to use it to control an air-valve when use "Air compressor" as air-assist. Faster action

- Use the same output to trigger a timer/counter for counting laser usage.

- IN1: Door open protect (pulled to GND is closed)

- Other I/O are "NA" and reserved for future expansion

- Warning: TTL is 24V! Still, OUT1/2 are not powerful enough to drive a classical relais.