CNC router build

Jump to navigation

Jump to search

| CNC Mill Release status: experimental [box doku] | |

|---|---|

| Description | |

| Author(s) | Tarwin |

| Last Version | v0.1 |

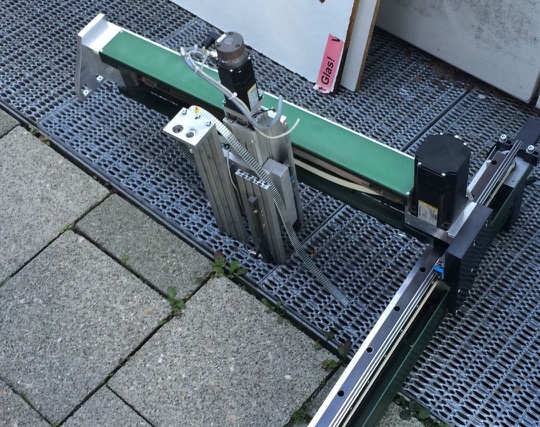

We want to use the big-ass CNC portal Thomas rescued from the trash to build a CNC router.

Goals

- Mill Aluminium!

- route PCBs

- be open for extensions, easy tool change

Hardware

Motor System

X & Y Motors

Z Motor

- Berger-Lahr VRDM368 50LNBOB

- brake needs 24V to loosen, works.

Motor controllers

- 3x JMC 3M860

Power supplies

- 3x 70V 400W from China

Motor cabeling

Z axis

- 1 = U

- 2 = V

- 3 = W

- 4 = NC

- 5 = break brown cable

- 6 = break white cable

X axis

- 1 = U

- 2 = V

- 3 = W

- 4 = NC

- 5 = NC

- 6 = NC

Endstops

X & Y

- Type unknown

- Seems to be an Solid-state Auto Switch, not just a Reed sensor, same pinout as the SMC

Z

- SMC D-F9H (datasheet) (Solid-state Auto Switch, works like a PNP transistor)

- Omron EE-SX870p Photomicrosensor (datasheet)

Electrical

- all endstops can be driven with 5 to 24V.

- Pinout is: brown: VCC / blue: GND / black: Signal

- Pinout on X: brown: VCC / green: GND / white: Signal

- all have a red led which goes out if they sense something

- Some input here

Endstop RJ45 connector

- - Signal Z-

- - Signal Z+

- - VCC (5-24V) (Brown)

- - Signal Y-

- - GND (Orange)

- - Signal Y+

- - Signal X+

- - Signal X-

List Left Sub D 25 Pol connector

- - 1 Red Cable Driver X

- - 2 Black Cable Driver X

- - 3 Green Cable Driver X

- - 4 Gray Cable Driver X

- - 5 Red Cable Driver Y

- - 6 Black Cable Driver Y

- - 7 Green Cable Driver Y

- - 8 Gray Cable Driver Y

- - 9 Red Cable Driver Z

- - 10 Black Cable Driver Z

- - 11 Green Cable Driver Z

- - 12 Gray Cable Driver Z

- - 13 Free

- - 14 Endstop Blue Cable RJ45=4 -> Signal Y-

- - 15 Endstop Blue/White Cable RJ45=5 -> GND (Orange)

- - 16 Endstop Orange Cable RJ45=2 -> Signal Z+

- - 17 Endstop Orange/White Cable RJ45=1 ->Signal Z-

- - 18 Endstop Green Cable RJ45=6 ->Signal Y+

- - 19 Endstop Green/White Cable RJ45=3 ->VCC (5-24V)(Brown)

- - 20 Endstop Brown Cable RJ45=8 -> Signal X+

- - 21 Endstop Brown/White Cable RJ45=7 -> Signal X-

- - 22 Free

- - 23 Free

- - 24 Free

- - 25 Free

List Right Sub D 25 Pol connector

- - 1 Not Halt Ader 1

- - 2 Not Halt Ader 2

- - 3

- - 4

- - 5

- - 6

- - 7

- - 8

- - 9

- - 10

- - 11

- - 12 Bremse Ader 5

- - 13 Bremse Ader 6

- - 14

- - 15

- - 16

- - 17

- - 18

- - 19

- - 20

- - 21

- - 22

- - 23

- - 24

- - 25

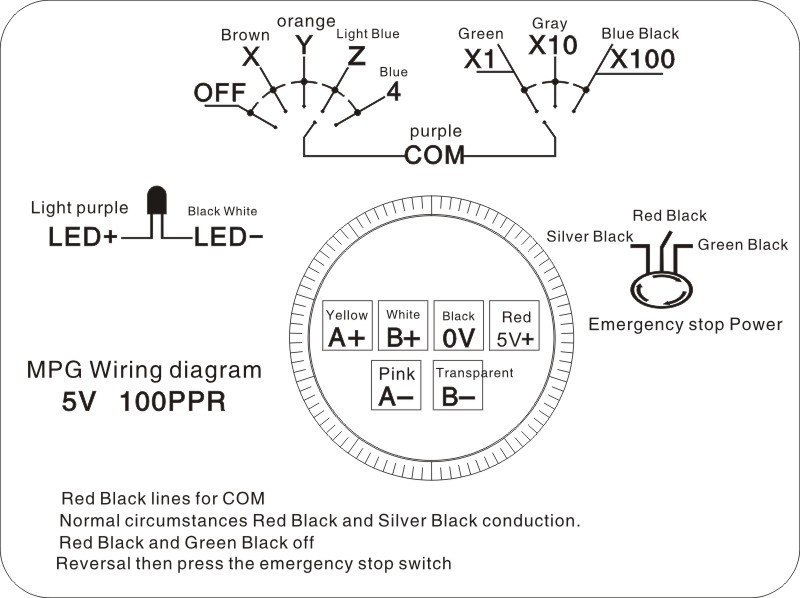

Handwheel

Bought from AliExpress, [page]

Controller

Software

Sub-projects

Fix up portal

- The portal needs to put together and fixed up

- Put portal together, replace belt - done

- identifiy / Test endstops - done

- Build portal frame - in progress (Thomas E)

- Try Z axis brake - done

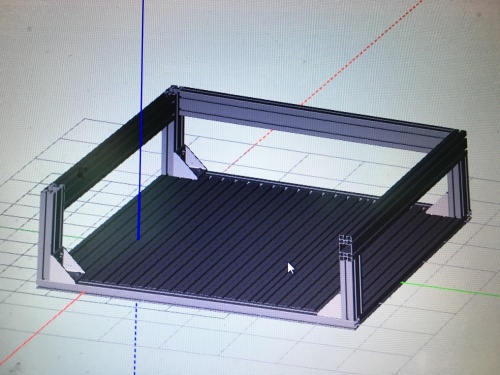

Frame and table

- The X Axis is raised, the linear bearing runs far above the tool head. This implies a high center of gravity.

- Frame needs to be very stable

- Old workbench?

First draft:

Tool head

- needs to be powerful (Aluminium) and precise (pcbs)

- Find matching Spindle with driver and cooling - done

- Bought this: 2.2kw wassergekühlte Frässpindel

- This can be controlled manually on the inverter or over serial.

- needs its own fuse and a fault current fuse (FI Schutzschalter)

- Technical data:

- 2.2kW / 8,000 - 24,000 RPM

- ER20 spring collets (Spannbuchsen)

- Driver: HY02D223B

- water cooled

Software & Controller

- What will tell the drivers what to do? PC/parallel port, Mikrokontroller, old CNC hardware, ...

- Hardware? What do we need?

- Main page for this: CNC_router_software_eval

Pictures

Last picture of the portal before it ware put apart and brought to the space