LaserCutter/Technical Details: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

=== Cooling === | |||

Demineralised water. | |||

=== Laser Controller === | === Laser Controller === | ||

Our laser controller is a Trocen AWC7824. The manual is located at [[File:AWC7813 motion controller user manual RV1.2.pdf]] | Our laser controller is a Trocen AWC7824. The manual is located at [[File:AWC7813 motion controller user manual RV1.2.pdf]] | ||

| Line 42: | Line 46: | ||

=== Mirrors === | === Mirrors === | ||

* use copper-backed or molybdenum-backed mirrors. Do not use silicone backed mirrors. | * use copper-backed or molybdenum-backed mirrors. Do not use silicone backed mirrors. | ||

* cleaning process: '''to be documented''' | |||

Revision as of 15:04, 30 April 2023

Cooling

Demineralised water.

Laser Controller

Our laser controller is a Trocen AWC7824. The manual is located at File:AWC7813 motion controller user manual RV1.2.pdf

Laser Safety System

- Using OpenLaserSafety (v1.0 at the time of writing) designed by Home of Making e.V.

- Outputs a single master signal to the laser controller

- Signaling to an i2c LED board

- Logs can be fetched by a Wemos D1 Mini

Checks the following sensors:

- Pressure Sensor to check if the exhaust is on and filter not congested (Honeywell HSCMRRD002NDAA5)

- Dip switch for an alternative exhaust check

- Flow & Water temp sensor (this one in 1/2")

- Lid status (separate for L/R sensor)

- Fire suppression system status (currently not in use)

- External machine unlock (currently not in use)

Sensor 'bus' cable to back

There is a big 12 wire core cable that runs from the safety board to the back of the laser, terminated on a screw terminal block.

| Color | Function | Pin on terminal block |

|---|---|---|

| brown | 5V | 1 |

| white | 3.3V | 2 |

| black | Ground | 3 |

| yellow | Pressure sensor | 4 |

| green | Exhaust flap | 5 |

| purple | Temperature sensor | 6 |

| grey | Flow sensor | 7 |

| blue | NC | 8 |

Mirrors

- use copper-backed or molybdenum-backed mirrors. Do not use silicone backed mirrors.

- cleaning process: to be documented

Logging

We installed a data logger to keep track of the usage hours. The logger tracks the time the air assist is on, just about the runtime the laser controller displays for a job. We want to use this to track the working hours of the laser tube, but if you want to check how long your laser cutting jobs took, feel free to check that here as well:

Additional Parts

- Gas spring, Price 24€, Manufacturer Shockex, Part number 1181202100, Amazon, Force: 320 N, Outer diameter 1: 18 mm, outer diameter 2: 8 mm, Stroke length: 187 mm, Lenght: 468 mm

- LED-Streifen 12V Kaltweiß

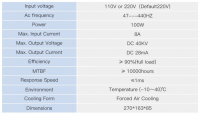

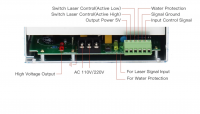

High voltage power supply

WaveTopSign HY-DY13 100W Co2 Laser Power Supply For RECI

Wiring

Pre 2022 maintenance wiring diagram

Out of date Laser Controller pinout (old controller)

Controller pins:

- OUT1: Output "Low" when XY start to move. OK to use this output to control air-pump On or Off as "Air-pump" take time to pump air out and slow

- OUT2: Output "Low" when laser is firing:

- Note that there is no output when XY is moving. It is ideal to use it to control an air-valve when use "Air compressor" as air-assist. Faster action

- Use the same output to trigger a timer/counter for counting laser usage.

- IN1: Door open protect (pulled to GND is closed)

- Other I/O are "NA" and reserved for future expansion

- Warning: TTL is 24V! Still, OUT1/2 are not powerful enough to drive a classical relais.