CNC 3020 Pro Max: Difference between revisions

Spacezhang (talk | contribs) (Wiki Content update, Bit storage reorganized) |

Spacezhang (talk | contribs) No edit summary |

||

| Line 360: | Line 360: | ||

== Feedback and suggestions == | == Feedback and suggestions == | ||

If you have any feedback, request or suggestions in regard to this project and wiki page, please feel free to contach me or simply edit this section of wiki.<br> | If you have any feedback, request or suggestions in regard to this project and wiki page, please feel free to contach me or simply edit this section of wiki.<br> | ||

This machine is currently maintained by @space.zhang (Yichen Zhang) | |||

[[Category:Project]] | [[Category:Project]] | ||

[[Category:Workshop]] | [[Category:Workshop]] | ||

[[Category:Inventory]] | [[Category:Inventory]] | ||

Revision as of 21:45, 21 September 2024

Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing!

Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing!  To use this machine the "CNC beginner training" workshop is mandatory!

To use this machine the "CNC beginner training" workshop is mandatory!| CNC 3020 Pro Max Release status: experimental [box doku] | |

|---|---|

| |

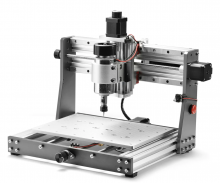

| Description | Milling/Engraving Machine |

| Author(s) | Yichen Zhang (Spacezhang) |

General Introduction

A small but full-featured cnc running GRBL donated to the lab for use, brought to you and maintained by Yichen.

What is the CNC 3020 Pro Max V2?

The CNC 3020 Pro Max V2 is a generic engraving machine. This machine can be used to cut anything from wood to aluminium and is very good for getting started and learn how to use a CNC machine and how It works.

Course Material

Presentation:

Handout: TBD

Basics and Tutorials

Here are some excellent resources to begin your journey with the machine. It's highly recommended to explore them if you can.

General CNC Basics

- CNC Dummies For Routers , A humorous introduction to the absolute basic concept of CNC Machining by This Old Tony

- Beginners Guide to CNC Bits - Including Speeds and Feeds from James Dean Designs

- Beginners guide to desktop CNC software from James Dean Designs

Machine Specific Introduction & Review

- Genmitsu 3020-PRO MAX V2 CNC Router Review from Doresoom Tool Reviews

- Sainsmart Genmitsu 3018 Pro review and tutorial from Teaching Tech

Guides & Tutorials

- Intro to Carbide Create and Making Gcode by Carbide Create

Advanced Guides

Using the machine with Fusion360:

This is where I started, although it is for the CNC 3018 the procedure is the same, the CNC 3020 is just a slighly bigger, more safe and more beefed up version of the CNC 3018.

Software Setup & Introduction

Software

Working windows software bundle for controlling the machine and for PCB Milling: https://drive.google.com/drive/folders/1bQ-ewmTWgRL_v9L2HsZoTOGtxflSw3Ma?usp=sharing

This is Preferred if you are using Windows as we can guarantee it works. Windows Driver also Included

CAM Options

| Name | Details | Link |

|---|---|---|

| Carbide Create V6 |

|

https://carbide3d.com/carbidecreate/download6 |

| Openbuilds opencam |

|

https://cam.openbuilds.com/ |

| Fusion 360 CAM |

|

https://www.autodesk.com/products/fusion-360/personal |

others

- https://grid.space/kiri/ A new web based free 3D CAM option! Kiri:Moto (Still TBT)

Tutorial coming soon, till then please search on youtube or ask for instructions on slack

Some Gcode Sender options

Control via your computer

To control the machine like positioning and execution of the instructions, it is required to run specific software and connect to the machine via USB - which provides a serial connection. It might be required to manually install a driver in order to use the serial connection.

Search for a driver called CH340 or CH341 provided by manufacturer WCH. The instructions provided by Sparkfun might be helpful [1]

For Windows users, the GRBL Candle software is a good choice for controlling and sending GCode to the machines. It is technically also usable on linux and mac, but it is untested.

For Mac's which are newer, GRBL Candel might not work due to some newer mac features. Please use CNCjs (Verified Working also with M1 Chip Mac with the machine) or UniversalGcodeSender.

| Name | Details | Link |

|---|---|---|

| GRBL Candel (Preferred for Windows) | Free, Open Source, WIN (Mac/Linux does not really work due to software from 2017) | https://github.com/Denvi/Candle |

| CNCjs (Preferred Second Choice) | Free, Open Source, WIN/MAC/LINUX | https://github.com/cncjs/cncjs/releases |

| universal gcode sender | Free, Open Source, WIN/MAC/LINUX (Tested with Mac) | https://universalgcodesender.com/download/ |

| Openbuilds Control | Free, Open Source, WIN/MAC/LINUX | https://software.openbuilds.com/ |

| bCNC | Free, Open Source, WIN/MAC/LINUX | https://github.com/vlachoudis/bCNC |

alternative option

There is also a offline Gcode Sender avaliable for use where Gcode can be loaded onto the SD Card and send to the machine. It is located in the accessoir drawer.

Instructions for different materials

Wood Engraving / Milling

[Detail comming soon]

PCB Engraving

Use Levelling! [Detail comming soon]

Acrylic Engraving / Milling

[Detail comming soon]

Test Gcode

[Detail comming soon]

Maintanence

[Detail comming soon]

Avaliable CNC Routing Bits

We currently have diverse bits at the lab, the majority of them are 3.175mm (1/8 Inch) shaft diameter.

- V Bits 15 / 20 / 25 /30 / 40 / 60 degree

- Corncob cutting bits 0.8 – 3.175 mm

- Single / Double flute upward cutting bits 3.175mm, 2mm

- Double flute 3.175mm Ball end bits

- Flat Endmill of diverse sizes

- 1 Inch planning bit with 6mm Shaft

- More are comming

Material settings

- For now, please use the rough estimate till we figure the value out for each bit!

- 3.175mm Bits:

- MDF & Softwood: 3.175mm single flute no more then 600mm/min, 2mm single flute no more then 400 mm/min, double flute 1.5 times the Feedrate

- Acrylic: 3.175mm single flute no nore then 300mm/min, 2mm single flute no more then 200 mm/min, double flute 1.5 times the Feedrate

- Aluminium: 2mm double flute 20mm / min, plundge rate 20mm / min(More testing need to be done)

Spindle speed: 10000 (Not actually at this speed, but for controller)

Plundge rate: 200mm / min to 400 mm / min

Pass depth: half the bit cutting size

- Engraving Acrylic: Use 25deg Vbit spiral cutter,

- Feedrate: 300/min, Plundge rate: 200mm/min, cutting depth: 0.3mm

Soft Wood (MDF, Plywood, Fir, spruce and pine etc.)

Work in progress. Comming Soon (Targeting June 2024)

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| XCAN Single Flute Nanoblue Coated | Single | 3.175mm | 3.175mm | 500 mm / min | 200 mm / min | 1.5mm | End Mill 3.175 mm |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Hard Wood (oak, maple, cherry, walnut, mahogany, ash etc.)

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Soft Plastics (PE, PVC, PU etc.)

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Hard Plastics (PET, PP, ABS, POM etc.)

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Acrylic (Also known as Plexiglass)

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Aluminium

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Brass

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Copper

| Bit Type | Number of Flute | Shank Diameter | Cutting Diameter | Recommended Feed Rate | Recommended Plundge Rate | Recommended Depth of Cut | Example Bit Name |

|---|---|---|---|---|---|---|---|

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

| Example | Example | Example | Example | Example | Example | Example | Example |

Acceptable work piece materials

Engrave/ Cut

- MDF / HDF

- Softwood, Hardwood, Plywood

- Acrylic

- PCB

- Aluminium, Brass & More

Technical Documentations

The Machine:

Spindle currently in use:

Official Resource Page from Saintsmart:

Specifications

Mechanical Specifications

- Type: Milling / Engraving machine

- Machine dimensions: 484 x 394 x 388mm (19.04” x 15.49” x 15.28”)

- Working area: 300 x 205 x 78 mm (11.81″ x 8.07″ x 3.07″)

- Max Speed: 2000mm / min

- Frame: Extruded Aluminum, All Metal

- Motion: NEMA 17, 47mm Stepper motors

- Stepper Driver: TB67S109

- Power Supply: 48V 8.3A

- Running / Reposition Accuracy: <= +- 0.1mm

- Materials: Woods, Plastics, PVCs, soft aluminum (6061), Nylon, Acrylic, PCBs

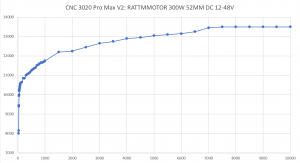

Spindle

- Motor: 300W 52MM DC 12-48V CNC Spindel Air cooled 12000U/min

- Cooling Fan: Internal

- Overall Size: 20,5 x 6,8 x 6,8 cm; 867 Gramm

- Collets: ER 11

- Actual measured Spindle Speed (Without Load): 13500 U/min

Controll Board

- Genmitsu custome control board

- Running GRBL 1.1f ARM32

- Interface Compatibility: Windows, Mac OS, Linux

- Height Probe, Hand Wheel & Air control connection

- Up to 4A Laser connection avaliable

Current GRBL Settings

$0=10 (step pulse,usec) $1=25 (step idle delay,msec) $2=0 (stepport invert mask) $3=2 (dirport invert mask) $4=0 (stepenable invert,bool) $5=1 (lims pin invert,bool) $6=1 (probe pin invert,bool) $10=1 (status report mask) $11=0.010 (junction deviation) $12=0.002 (arc tolerance,mm) $13=0 (report inches,bool) $20=0 (soft limits,bool) $21=1 (hard limits,bool) $22=1 (home cycle,bool) $23=3 (homing dir invert mask) $24=100.000 (homing feed,mm/min) $25=500.000 (homing seek,mm/min) $26=250 (homing debounce,msec) $27=2.000 (homing pull-off,mm) $30=10000 (maximum spindle speed,rpm) $31=0 (minimum spindle speed,rpm) $32=0 (laser mode enable,bool) $100=800.000 (x axis pulse:step/mm) $101=800.000 (y axis pulse:step/mm) $102=800.000 (z axis pulse:step/mm) $110=2000.000 (x axis max rata:mm/min) $111=2000.000 (y axis max rata:mm/min) $112=2000.000 (z axis max rata:mm/min) $120=50.000 (x axis acceleration:mm/s^2) $121=50.000 (y axis acceleration:mm/s^2) $122=50.000 (z axis acceleration:mm/s^2) $130=300.000 (x aixs max travel:mm) $131=200.000 (y aixs max travel:mm) $132=80.000 (z aixs max travel:mm) ok

Sample cuts and demonstration projects

Change Log

Note: Aiming for Middle 2024 to finish the documentation. Till that time, if you have any questions in regards of this machine, please contact @spacezhang on slack.

- 16.11.2023: Machine has been assembles and brought to the lab.

- 11.12.2023: Wiki Page has been created

- 27.12.2023: New Spindle Arrived, runout improved from 0.11 to 0.03, Spindle Speed manually measured

- 25.01.2024: New Eurobox container has arrived and the machine is now on the bottom shelve in the workshop! (As discussed in Plenum)

- 21.09.2024: Wiki Content update, Bit storage reorganized.

<\br> Also: We have more new bits for use!

Feedback and suggestions

If you have any feedback, request or suggestions in regard to this project and wiki page, please feel free to contach me or simply edit this section of wiki.

This machine is currently maintained by @space.zhang (Yichen Zhang)