CNC 3020 Pro Max: Difference between revisions

No edit summary |

Spacezhang (talk | contribs) No edit summary |

||

| Line 2: | Line 2: | ||

<big>Warning: This page is still work in progress, please contact Yichen Zhang (Spacezhang) or Phier on Slack if more information are needed.</big> </div> <noinclude> | <big>Warning: This page is still work in progress, please contact Yichen Zhang (Spacezhang) or Phier on Slack if more information are needed.</big> </div> <noinclude> | ||

<div style="background-color:#FFFFFF; padding: 1.2rem; margin-top: 0.5em; border: 1px solid #c8ccd1; border-top-color:#FF6347; border-top-width: .4rem; border-radius: .20rem; box-shadow: 2px 2px #F7F8F9;"> | <div style="background-color:#FFFFFF; padding: 1.2rem; margin-top: 0.5em; border: 1px solid #c8ccd1; border-top-color:#FF6347; border-top-width: .4rem; border-radius: .20rem; box-shadow: 2px 2px #F7F8F9;"> | ||

<big><center>[[Image:Attention.png|50px]] Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing! [[Image:Attention.png|50px]] | <big><center>[[Image:Attention.png|50px]] Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing! [[Image:Attention.png|50px]] To use this machine the "CNC beginner training" workshop is mandatory!</center></big> </div> <noinclude> | ||

{{project | {{project | ||

| Line 9: | Line 9: | ||

|author = Yichen Zhang | |author = Yichen Zhang | ||

|username = Spacezhang | |username = Spacezhang | ||

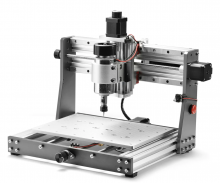

|image = CNC-3020-Pro-Max-V2.png | |||

|platform = | |platform = | ||

|license = | |license = | ||

| Line 18: | Line 19: | ||

A small but full-featured cnc running GRBL donated to the lab for use, brought to you and maintained by Yichen. | A small but full-featured cnc running GRBL donated to the lab for use, brought to you and maintained by Yichen. | ||

== What is the CNC 3020 Pro Max? == | == What is the CNC 3020 Pro Max V2? == | ||

The CNC | The CNC 3020 Pro Max V2 is a generic engraving machine. This machine can be used to cut anything from wood to aluminium and is very good for getting started and learn how to use a CNC machine and how It works. | ||

== Software Setup & Introduction == | |||

===<div id="Software">Software</div>=== | |||

For Windows users, the [https://github.com/Denvi/Candle GRBL Candle software] is a good choice for controlling and sending GCode to the machines. It is technically also usable on linux and mac, but it is untested. | |||

Mac: For newer version of mac GRBL Candel might not work due to some newer mac features. Instead, the universalgcodesender or the openbuilds Gcode Sender could be used. | |||

Working software bundle for controlling the machine and for PCB Milling: <br> | |||

https://drive.google.com/drive/folders/1bQ-ewmTWgRL_v9L2HsZoTOGtxflSw3Ma?usp=sharing<br> | |||

'''Some Gcode Sender options:''' <br> | |||

universal gcode sender [Free, Open Source, WIN/MAC/LINUX](Tested with Mac) | |||

* https://universalgcodesender.com/download/ | |||

bCNC [Free, Open Source, WIN/MAC/LINUX] | |||

* https://github.com/vlachoudis/bCNC | |||

Openbuilds Control [Free, Open Source, WIN/MAC/LINUX] | |||

* https://software.openbuilds.com/ | |||

'''CAM Options''' <br> | |||

Carbide Create V6 Software for 2D Routing [Free, Tested, Recommended, WIN/MAC] (Use version V6 as later version requires subscription): | |||

* https://carbide3d.com/carbidecreate/download6 | |||

Openbuilds opencam [Free, Tested, Web-Based or Local, WIN/MAC/LINUX]<br> | |||

https://cam.openbuilds.com/<br> | |||

Fusion 360 CAM for proper 3D Routing [Free*, Tested, Recommended] | |||

* (More advanced and requires more time to learn, but very powerful and is a requirement for the big CNC) | |||

* https://www.autodesk.com/products/fusion-360/personal | |||

Tutorial comming soon, till then please search on youtube or ask for instructions on slack | |||

===== Wood Engraving / Milling ===== | |||

[Detail comming soon] | |||

===== PCB Engraving ===== | |||

[Detail comming soon] | |||

===== Acrylic Engraving / Milling ===== | |||

[Detail comming soon] | |||

===== Test Gcode===== | |||

[Detail comming soon] | |||

== Maintanence == | |||

[Detail comming soon] | |||

== Material settings == | |||

* Wood 3.15mm Endmill<br> | |||

Feed speed: TBD/s<br> | |||

Spindle speed: 10000 (Not actually at this speed, but for controller)<br> | |||

Pass depth: 1.5mm | |||

===== Acceptable work piece materials ===== | ===== Acceptable work piece materials ===== | ||

| Line 27: | Line 72: | ||

* Acrylic | * Acrylic | ||

* PCB | * PCB | ||

* | * Aluminium, Brass & More | ||

= Technichal Documentations = | = Technichal Documentations = | ||

The Machine: | |||

* https://www.sainsmart.com/products/3020-pro-max-v2 | |||

Spindle currently in use: | |||

* https://www.amazon.de/dp/B09VK9DQNY | |||

Official Resource Page from Saintsmart: | |||

* https://docs.sainsmart.com/article/3batun0e7p-3020-pro-max-v-2 | |||

== Specifications == | == Specifications == | ||

=====Mechanical Specifications===== | =====Mechanical Specifications===== | ||

* Type: Milling / Engraving machine | * Type: Milling / Engraving machine | ||

* Machine dimensions: x | * Machine dimensions: 484 x 394 x 388mm (19.04” x 15.49” x 15.28”) | ||

* Working area: 300 x 205 x 78 mm (11.81″ x 8.07″ x 3.07″) | * Working area: 300 x 205 x 78 mm (11.81″ x 8.07″ x 3.07″) | ||

* Frame: Extruded Aluminum | * Max Speed: 2000mm / min | ||

* | * Frame: Extruded Aluminum, All Metal | ||

* Motion: NEMA 17, 47mm Stepper motors | |||

* Stepper Driver: TB67S109 | |||

* Power Supply: 48V 8.3A | |||

* Running / Reposition Accuracy: <= +- 0.1mm | |||

* Materials: Woods, Plastics, PVCs, soft aluminum (6061), Nylon, Acrylic, PCBs | * Materials: Woods, Plastics, PVCs, soft aluminum (6061), Nylon, Acrylic, PCBs | ||

===== Spindle===== | ===== Spindle===== | ||

* Motor: | * Motor: 300W 52MM DC 12-48V CNC Spindel Air cooled 12000U/min | ||

* Cooling Fan: Internal | * Cooling Fan: Internal | ||

* Overall Size: | * Overall Size: 20,5 x 6,8 x 6,8 cm; 867 Gramm | ||

* Collets: ER 11 | * Collets: ER 11 | ||

* Actual measured Spindle Speed (Without Load): 13500 U/min | |||

===== Routing Bits===== | ===== Routing Bits===== | ||

* Currently | * Currently mostly 3.175 mm (1/8 Inch) Bits Available | ||

* V Bits 20 / 40 / 60 degree | * V Bits 20 / 30 / 40 / 60 degree | ||

* Multifunctional cutting bits 0.8 – 3.175 mm | * Multifunctional cutting bits 0.8 – 3.175 mm | ||

* Single flute upward cutting bits 3.175mm, 2mm | * Single flute upward cutting bits 3.175mm, 2mm | ||

* 3.175mm Ball end double flute bits | * 3.175mm Ball end double flute bits | ||

* More are comming | |||

===== Controll Board===== | ===== Controll Board===== | ||

* | * Genmitsu custome control board | ||

* Running GRBL 1.1f | * Running GRBL 1.1f ARM32 | ||

* Interface Compatibility: Windows, Mac OS, Linux | * Interface Compatibility: Windows, Mac OS, Linux | ||

* Height Probe, Hand Wheel & Air control connection | |||

* Up to 4A Laser connection avaliable | |||

=== Current GRBL Settings === | |||

<pre> | |||

$0=10 (step pulse,usec) | |||

$1=25 (step idle delay,msec) | |||

$2=0 (stepport invert mask) | |||

$3=2 (dirport invert mask) | |||

$4=0 (stepenable invert,bool) | |||

$5=1 (lims pin invert,bool) | |||

$6=1 (probe pin invert,bool) | |||

$10=1 (status report mask) | |||

$11=0.010 (junction deviation) | |||

$12=0.002 (arc tolerance,mm) | |||

$13=0 (report inches,bool) | |||

$20=0 (soft limits,bool) | |||

$21=1 (hard limits,bool) | |||

$22=1 (home cycle,bool) | |||

$23=3 (homing dir invert mask) | |||

$24=100.000 (homing feed,mm/min) | |||

$25=500.000 (homing seek,mm/min) | |||

$26=250 (homing debounce,msec) | |||

$27=2.000 (homing pull-off,mm) | |||

$30=10000 (maximum spindle speed,rpm) | |||

$31=0 (minimum spindle speed,rpm) | |||

$32=0 (laser mode enable,bool) | |||

$100=800.000 (x axis pulse:step/mm) | |||

$101=800.000 (y axis pulse:step/mm) | |||

$102=800.000 (z axis pulse:step/mm) | |||

$110=2000.000 (x axis max rata:mm/min) | |||

$111=2000.000 (y axis max rata:mm/min) | |||

$112=2000.000 (z axis max rata:mm/min) | |||

$120=50.000 (x axis acceleration:mm/s^2) | |||

$121=50.000 (y axis acceleration:mm/s^2) | |||

$122=50.000 (z axis acceleration:mm/s^2) | |||

$130=300.000 (x aixs max travel:mm) | |||

$131=200.000 (y aixs max travel:mm) | |||

$132=80.000 (z aixs max travel:mm) | |||

ok | |||

</pre> | |||

== Feedback and suggestions == | == Feedback and suggestions == | ||

If you have any feedback, request or suggestions in regard to this project and wiki page, please feel free to contach me or simply edit this section of wiki.<br> | If you have any feedback, request or suggestions in regard to this project and wiki page, please feel free to contach me or simply edit this section of wiki.<br> | ||

Revision as of 21:04, 5 January 2024

Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing!

Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing!  To use this machine the "CNC beginner training" workshop is mandatory!

To use this machine the "CNC beginner training" workshop is mandatory!| CNC 3020 Pro Max Release status: experimental [box doku] | |

|---|---|

| |

| Description | Milling/Engraving Machine |

| Author(s) | Yichen Zhang (Spacezhang) |

General Introduction

A small but full-featured cnc running GRBL donated to the lab for use, brought to you and maintained by Yichen.

What is the CNC 3020 Pro Max V2?

The CNC 3020 Pro Max V2 is a generic engraving machine. This machine can be used to cut anything from wood to aluminium and is very good for getting started and learn how to use a CNC machine and how It works.

Software Setup & Introduction

Software

For Windows users, the GRBL Candle software is a good choice for controlling and sending GCode to the machines. It is technically also usable on linux and mac, but it is untested.

Mac: For newer version of mac GRBL Candel might not work due to some newer mac features. Instead, the universalgcodesender or the openbuilds Gcode Sender could be used.

Working software bundle for controlling the machine and for PCB Milling:

https://drive.google.com/drive/folders/1bQ-ewmTWgRL_v9L2HsZoTOGtxflSw3Ma?usp=sharing

Some Gcode Sender options:

universal gcode sender [Free, Open Source, WIN/MAC/LINUX](Tested with Mac)

bCNC [Free, Open Source, WIN/MAC/LINUX]

Openbuilds Control [Free, Open Source, WIN/MAC/LINUX]

CAM Options

Carbide Create V6 Software for 2D Routing [Free, Tested, Recommended, WIN/MAC] (Use version V6 as later version requires subscription):

Openbuilds opencam [Free, Tested, Web-Based or Local, WIN/MAC/LINUX]

https://cam.openbuilds.com/

Fusion 360 CAM for proper 3D Routing [Free*, Tested, Recommended]

- (More advanced and requires more time to learn, but very powerful and is a requirement for the big CNC)

- https://www.autodesk.com/products/fusion-360/personal

Tutorial comming soon, till then please search on youtube or ask for instructions on slack

Wood Engraving / Milling

[Detail comming soon]

PCB Engraving

[Detail comming soon]

Acrylic Engraving / Milling

[Detail comming soon]

Test Gcode

[Detail comming soon]

Maintanence

[Detail comming soon]

Material settings

- Wood 3.15mm Endmill

Feed speed: TBD/s

Spindle speed: 10000 (Not actually at this speed, but for controller)

Pass depth: 1.5mm

Acceptable work piece materials

Engrave/ Cut

- MDF / HDF

- Softwood, Hardwood, Plywood

- Acrylic

- PCB

- Aluminium, Brass & More

Technichal Documentations

The Machine:

Spindle currently in use:

Official Resource Page from Saintsmart:

Specifications

Mechanical Specifications

- Type: Milling / Engraving machine

- Machine dimensions: 484 x 394 x 388mm (19.04” x 15.49” x 15.28”)

- Working area: 300 x 205 x 78 mm (11.81″ x 8.07″ x 3.07″)

- Max Speed: 2000mm / min

- Frame: Extruded Aluminum, All Metal

- Motion: NEMA 17, 47mm Stepper motors

- Stepper Driver: TB67S109

- Power Supply: 48V 8.3A

- Running / Reposition Accuracy: <= +- 0.1mm

- Materials: Woods, Plastics, PVCs, soft aluminum (6061), Nylon, Acrylic, PCBs

Spindle

- Motor: 300W 52MM DC 12-48V CNC Spindel Air cooled 12000U/min

- Cooling Fan: Internal

- Overall Size: 20,5 x 6,8 x 6,8 cm; 867 Gramm

- Collets: ER 11

- Actual measured Spindle Speed (Without Load): 13500 U/min

Routing Bits

- Currently mostly 3.175 mm (1/8 Inch) Bits Available

- V Bits 20 / 30 / 40 / 60 degree

- Multifunctional cutting bits 0.8 – 3.175 mm

- Single flute upward cutting bits 3.175mm, 2mm

- 3.175mm Ball end double flute bits

- More are comming

Controll Board

- Genmitsu custome control board

- Running GRBL 1.1f ARM32

- Interface Compatibility: Windows, Mac OS, Linux

- Height Probe, Hand Wheel & Air control connection

- Up to 4A Laser connection avaliable

Current GRBL Settings

$0=10 (step pulse,usec) $1=25 (step idle delay,msec) $2=0 (stepport invert mask) $3=2 (dirport invert mask) $4=0 (stepenable invert,bool) $5=1 (lims pin invert,bool) $6=1 (probe pin invert,bool) $10=1 (status report mask) $11=0.010 (junction deviation) $12=0.002 (arc tolerance,mm) $13=0 (report inches,bool) $20=0 (soft limits,bool) $21=1 (hard limits,bool) $22=1 (home cycle,bool) $23=3 (homing dir invert mask) $24=100.000 (homing feed,mm/min) $25=500.000 (homing seek,mm/min) $26=250 (homing debounce,msec) $27=2.000 (homing pull-off,mm) $30=10000 (maximum spindle speed,rpm) $31=0 (minimum spindle speed,rpm) $32=0 (laser mode enable,bool) $100=800.000 (x axis pulse:step/mm) $101=800.000 (y axis pulse:step/mm) $102=800.000 (z axis pulse:step/mm) $110=2000.000 (x axis max rata:mm/min) $111=2000.000 (y axis max rata:mm/min) $112=2000.000 (z axis max rata:mm/min) $120=50.000 (x axis acceleration:mm/s^2) $121=50.000 (y axis acceleration:mm/s^2) $122=50.000 (z axis acceleration:mm/s^2) $130=300.000 (x aixs max travel:mm) $131=200.000 (y aixs max travel:mm) $132=80.000 (z aixs max travel:mm) ok

Feedback and suggestions

If you have any feedback, request or suggestions in regard to this project and wiki page, please feel free to contach me or simply edit this section of wiki.