CNC router build: Difference between revisions

BotoxBitch (talk | contribs) No edit summary |

BotoxBitch (talk | contribs) (→Goals) |

||

| (5 intermediate revisions by 2 users not shown) | |||

| Line 13: | Line 13: | ||

|username = Tarwin | |username = Tarwin | ||

|version = v1.1 | |version = v1.1 | ||

|update = 09.04. | |update = 09.04.21 -BotoxBitch | ||

|platform = | |platform = | ||

|license = | |license = | ||

| Line 30: | Line 30: | ||

* [https://www.cnc-controller.eu/shop/3d-messtaster/ 3D Probe] like this one (currently nice to have) | * [https://www.cnc-controller.eu/shop/3d-messtaster/ 3D Probe] like this one (currently nice to have) | ||

Current cost: 5€ per 60 minutes | |||

= Hardware = | = Hardware = | ||

| Line 162: | Line 165: | ||

== Controller -> Replaced with CSMIO/IP-M == | == Controller -> Replaced with CSMIO/IP-M == | ||

-> [[CNC_router_controller]] | -> [[CNC router build/CNC_router_controller|CNC router build/CNC_router_controller]] | ||

Manuals for CNC Controller: | Manuals for CNC Controller: | ||

| Line 198: | Line 201: | ||

[[CNC_router_software_eval]] Kept for Archiving. | [[Archive:CNC_router_software_eval]] Kept for Archiving. | ||

== Sub-projects == | == Sub-projects == | ||

| Line 210: | Line 213: | ||

** Build Table for better stability and moveability - done | ** Build Table for better stability and moveability - done | ||

** Build exhaust for spindle - in progress ( one printed part broke need redesign more stable and print again ) pipe and tube ared ordered | ** Build exhaust for spindle - in progress ( one printed part broke need redesign more stable and print again ) pipe and tube ared ordered | ||

** Create an holder for Water Tank + Cover for Power and pipe insert | ** Create an holder for Water Tank + Cover for Power and pipe insert - done | ||

** Front plate - | ** Front plate - done | ||

** Movement Mechanic for the front/top Cover - | ** Movement Mechanic for the front/top Cover - done | ||

** milling flat the area of the Vice | ** milling flat the area of the Vice - to do after redesign | ||

** create holder to be able to fix the vive in place ( in perfect angle ) | ** create holder to be able to fix the vive in place ( in perfect angle ) - to do after Redesign | ||

** Measure and drill the last holes of the spindle holder | ** Measure and drill the last holes of the spindle holder - Done | ||

** NEW: Replace The X-Beam and Z-Axis. This will allow for Ballscrews to be installed and make the machine more rigid, so milling alluminium precisely will become a real Thing. | ** NEW: Replace The X-Beam and Z-Axis. This will allow for Ballscrews to be installed and make the machine more rigid, so milling alluminium precisely will become a real Thing. | ||

** NEW: Raise enough money for this Project to happen. (approx. 1000-1200€ needed.) | ** NEW: Raise enough money for this Project to happen. (approx. 1000-1200€ needed.) | ||

| Line 229: | Line 232: | ||

==== Tool head ==== | ==== Tool head ==== | ||

[ | [[CNC_router_build/Technical_data|Technical Data of the stuff we bought]] | ||

* needs to be powerful (Aluminium) and precise (pcbs) | * needs to be powerful (Aluminium) and precise (pcbs) | ||

** Find matching Spindle with driver and cooling - done | ** Find matching Spindle with driver and cooling - done | ||

Latest revision as of 18:15, 4 May 2023

| Attention: Dangerous machine ahead | ||

|---|---|---|

| Use only at your own risk, and after proper instruction! ASK BERNHARD to get safety and instructions !!!before!!! turning it on. |

| CNC Mill Release status: beta [box doku] | |

|---|---|

| |

| Description | Ask Bernhard for instructions |

| Author(s) | Tarwin |

| Last Version | v1.1 (09.04.21 -BotoxBitch) |

We want to use the big-ass CNC portal Thomas rescued from the trash to build a CNC router.

Goals

- Mill Aluminium! (needs ballscrews to really work) see Subproject: Portal

- route PCBs

- be open for extensions, easy tool change (needs a very expensive ATC-Spindle and proper toolholding, expensive aswell)

- Add Tool Touch off and a small 3D Probe for extended Usability (Tool touch off is in the lab, needs to be hooked up and the machine to be configured)

- 3D Probe like this one (currently nice to have)

Current cost: 5€ per 60 minutes

Hardware

Motor System

X & Y Motors

Z Motor

- Berger-Lahr VRDM368 50LNBOB

- brake needs 24V to loosen, works.

Motor controllers

- 2x JMC 3M860 -- Manual: File:3M860.pdf

- 1x Another Stepper driver, different from the JMC 3M860 with a different cable configuration, which was bought as a replacment for a faulty JMC3M860 File:CWD3M860.pdf

Power supplies

- 3x 70V 400W from China

Motor cabeling

Z axis

- 1 = U

- 2 = V

- 3 = W

- 4 = NC

- 5 = break brown cable

- 6 = break white cable

X axis

- 1 = U

- 2 = V

- 3 = W

- 4 = NC

- 5 = NC

- 6 = NC

Endstops

X & Y

- Type unknown

- Seems to be an Solid-state Auto Switch, not just a Reed sensor, same pinout as the SMC

Z

- SMC D-F9H (datasheet) (Solid-state Auto Switch, works like a PNP transistor)

- Omron EE-SX870p Photomicrosensor (datasheet)

Electrical

- all endstops can be driven with 5 to 24V.

- Pinout is: brown: VCC / blue: GND / black: Signal

- Pinout on X: brown: VCC / green: GND / white: Signal

- all have a red led which goes out if they sense something

- Some input here

Endstop RJ45 connector -> Replaced

- - Signal Z-

- - Signal Z+

- - VCC (5-24V)

- - Signal Y-

- - GND

- - Signal Y+

- - Signal X+

- - Signal X-

As by 09.07.2020 the RJ45 Connector has been disposed of and the Limit Switches are connected directly to the CSMIO/IP-M

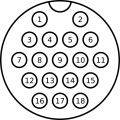

Handwheel

Bought from AliExpress, [page]

Pinout:

1 GND

2 +5V

3 A+

4 B+

5 A-

6 B-

7 Emergency Stop (pin 1)

8 Emergency Stop (pin 2)

9 LED+

10 LED-

11 COM

12 X

13 Y

14 Z

15 4

16 x1

17 x10

18 x100

Encoder Wheel

The wheel needs a +5V power supply, and outputs a slightly lower voltage on A+/B+/A-/B-. One step of the wheel goes through a full cycle. This is not a regular switch, so no connection can be measured.

It is a rotary encoder with grey code. Need to check 4 bit or 2 bit. Some arduino Librarys are available https://github.com/brianlow/Rotary Demotape (talk)

Emergency Stop

This is a standart Mushroom Knot

Inside are 2 simple normally closed switch.

one is connected to the control unit to stop the program

the second one is connected with the power switch so if pressed the Power for motors and spindle will be switched off ( power for the control unit stay on)

The two switches are needed for a two channel emergency stop. Cut off all energy with two separated contactor (Schütze). Demotape (talk)

LED

A red LED, 20mA standard current drive.

Selection Switches

These switches are connected through the "Enable" button on the left. No signal is received unless the button is pressed.

The X, Y, Z and 4 pins are connected to COM when the respective axis is selected, and the enable switch pressed.

The x1, x10 and x100 pins are connected to COM when the respective speed is selected, and the enable switch pressed.

Connection to Linux CNC

https://github.com/DylanVanAssche/LinuxCNC-Pendant/blob/master/LinuxCNCPendant.ino

The hand wheel is connected to an arduino.Hat With a Atmega 32u4 Microcontroller(Arduino Leonardo, Arduino Pro mini)? The Arduino is like as a keyboard and send only key presses. Demotape (talk)

Controller -> Replaced with CSMIO/IP-M

-> CNC router build/CNC_router_controller

Manuals for CNC Controller:

- File:CNC Controller.pdf Handsteuerung

- File:CNC Controller use in Mach3 Mill and Pin-Out.pdf Description of Pins of the controller board and how to operate it within Mach3 Mill

- File:Controller Board Relay Output Wiring.pdf Information for connecting the spindle to a relay and the controller

- File:Wiring for Endstops and Emergency Stop.pdf How to wire the endstops and the emergency stop

- File:PCI-Parallel-setting.pdf windows settings for using the parallel port

-> CSMIO/IP-M

- Manual for the Controller is on the CD and on the Mill PC

- DO NOT TINKER AROUND UNLESS SPEAKING TO DAVID / RENE / BERNHARD

Spindle

Connector Pins = Cable

1 = 1 2 = 2 3 = 3 4 = PE

Cable = controller side

Cable 1 = U Cable 2 = V Cable 3 = W PE Cable = E

Software

- Currently Using Mach3 as CNC Software. WORKS

- We are looking into Fusion360 as possible CAM. We got a Postprocessor, A few cycles are still subject to testing so there will be no Public release yet.

- We got a license for E-CAM aswell. NEED TO EVALUATE

Archive:CNC_router_software_eval Kept for Archiving.

Sub-projects

Fix up portal

- The portal needs to put together and fixed up

- Put portal together, replace belt - done

- identifiy / Test endstops - done

- Build portal frame - done

- Try Z axis brake - done

- Build Table for better stability and moveability - done

- Build exhaust for spindle - in progress ( one printed part broke need redesign more stable and print again ) pipe and tube ared ordered

- Create an holder for Water Tank + Cover for Power and pipe insert - done

- Front plate - done

- Movement Mechanic for the front/top Cover - done

- milling flat the area of the Vice - to do after redesign

- create holder to be able to fix the vive in place ( in perfect angle ) - to do after Redesign

- Measure and drill the last holes of the spindle holder - Done

- NEW: Replace The X-Beam and Z-Axis. This will allow for Ballscrews to be installed and make the machine more rigid, so milling alluminium precisely will become a real Thing.

- NEW: Raise enough money for this Project to happen. (approx. 1000-1200€ needed.)

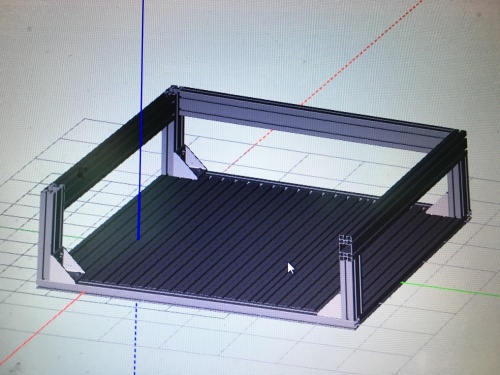

Frame and table

- The X Axis is raised, the linear bearing runs far above the tool head. This implies a high center of gravity.

- Frame needs to be very stable

- Old workbench?

First draft:

Tool head

Technical Data of the stuff we bought

- needs to be powerful (Aluminium) and precise (pcbs)

- Find matching Spindle with driver and cooling - done

- Bought this: 2.2kw wassergekühlte Frässpindel

- This can be controlled manually on the inverter or over serial.

- needs its own fuse and a fault current fuse (FI Schutzschalter)

- Technical data:

- 2.2kW / 8,000 - 24,000 RPM

- ER20 spring collets (Spannbuchsen)

- Driver: HY02D223B

- Manual of the driver

- water cooled

- NEW: ADD an old PC Radiator for additional Cooling

- NEW: Add an electric Valve for Pneumatics to enable automated Chip Blasting and Air / Mist Cooling

Software & Controller

- What will tell the drivers what to do? PC/parallel port, Mikrokontroller, old CNC hardware, ...

- Hardware? What do we need?

- Main page for this: CNC_router_software_eval

- NEW: Currently Running MACH3 with Fusion360 for Programming

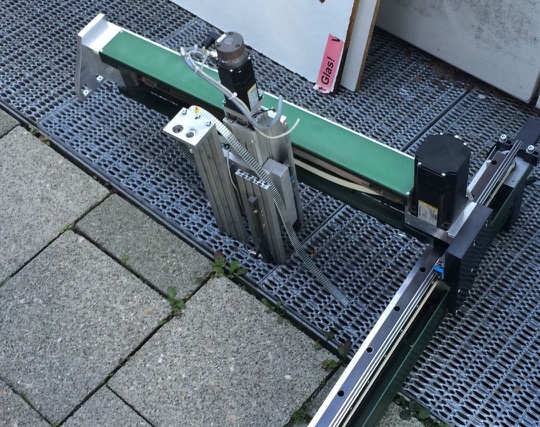

Pictures

Last picture of the portal before it ware put apart and brought to the space