CNC3018 Pro: Difference between revisions

Jump to navigation

Jump to search

Warning: This page is still a work in Progress, please contact Yichen Zhang (Spacezhang) on Slack if more Information is needed

Warning: This page is still a work in Progress, please contact Yichen Zhang (Spacezhang) on Slack if more Information is needed

Spacezhang (talk | contribs) (Partially updated explainations and added Fotos) |

Spacezhang (talk | contribs) No edit summary |

||

| Line 2: | Line 2: | ||

<big>Warning: This page is still a work in Progress, please contact Yichen Zhang (Spacezhang) on Slack if more Information is needed </big> </div> <noinclude> | <big>Warning: This page is still a work in Progress, please contact Yichen Zhang (Spacezhang) on Slack if more Information is needed </big> </div> <noinclude> | ||

<div style="background-color:#FFFFFF; padding: 1.2rem; margin-top: 0.5em; border: 1px solid #c8ccd1; border-top-color:#FF6347; border-top-width: .4rem; border-radius: .20rem; box-shadow: 2px 2px #F7F8F9;"> | <div style="background-color:#FFFFFF; padding: 1.2rem; margin-top: 0.5em; border: 1px solid #c8ccd1; border-top-color:#FF6347; border-top-width: .4rem; border-radius: .20rem; box-shadow: 2px 2px #F7F8F9;"> | ||

<big>Warning: Beware of the dangers of CNC machines | <big>Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing! Please contact Yichen Zhang (Spacezhang) for detailed explaination and tutorial </big> </div> <noinclude> | ||

{{project | {{project | ||

| Line 18: | Line 18: | ||

}} | }} | ||

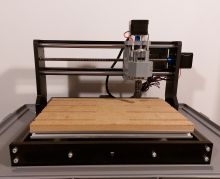

= General Introduction = | |||

A small but full-featured cnc running GRBL donated to the lab for use, brought to you and maintained by yichen zhang. | |||

[[File:CNC 3018 Pro Side.jpg|thumb|Side View]] | [[File:CNC 3018 Pro Side.jpg|thumb|Side View]] | ||

==What is the CNC 3018 Pro? == | |||

The CNC 3018 Pro is a generic engraving machine. This machine can be used to cut anything from wax to wood and is very good for getting started and learn how to use a CNC machine and how It works. | |||

===== Acceptable work piece materials ===== | |||

Engrave/ Cut | |||

* MDF / HDF | |||

* Softwood, Hardwood, Plywood | |||

* Acrylic | |||

* PCB | |||

* Very soft Aluminium (no harder than brass or aluminum 6061) (Detail untested) | |||

+ Height Map support | |||

== Current Position== | |||

[Comming soon] | [Comming soon] | ||

= Getting started = | |||

==Basic operation== | |||

* Change Router bits | * Change Router bits | ||

* Z Height map | * Z Height map | ||

* Change Spindle | * Change Spindle | ||

[Detail and Tutorial comming soon] | [Detail and Tutorial comming soon] | ||

== Software Setup & Introduction == | |||

'''Set up the machine -> connect to laptop -> move to origin -> load sample gcode -> start milling ''' | '''Set up the machine -> connect to laptop -> move to origin -> load sample gcode -> start milling ''' | ||

===== Wood Engraving / Milling ===== | |||

===== PCB Engraving ===== | |||

===== Acrylic Engraving / Milling ===== | |||

===== Test Gcode===== | |||

[Detail comming soon] | [Detail comming soon] | ||

== Maintanence == | |||

[Detail comming soon] | |||

== Material settings == | |||

= Machine Inventory = | |||

= Technichal Documentations = | |||

== Specifications == | == Specifications == | ||

=====Mechanical Specifications===== | |||

* Type: Milling / Engraving machine | * Type: Milling / Engraving machine | ||

* Machine dimensions: 330 x 400 x 240 mm (13.0″ x 15.7″ x 9.4″) | * Machine dimensions: 330 x 400 x 240 mm (13.0″ x 15.7″ x 9.4″) | ||

| Line 57: | Line 66: | ||

* Motion: NEMA 17 Stepper motors | * Motion: NEMA 17 Stepper motors | ||

===== Spindle===== | |||

* Motor: 775 motor, 24 V , ~8,000 RPM | * Motor: 775 motor, 24 V , ~8,000 RPM | ||

* Rated current: 1.2A @ 24V. | * Rated current: 1.2A @ 24V. | ||

* Cooling Fan: Internal | * Cooling Fan: Internal | ||

* Overall Size: 98x42mm, Full Round Type Ø5mm shaft. | * Overall Size: 98x42mm, Full Round Type Ø5mm shaft. | ||

* Collets: ER 11 | * Collets: ER 11 | ||

===== Routing Bits===== | |||

* Currently only 3.175 mm (1/8 Inch) Bits Available | * Currently only 3.175 mm (1/8 Inch) Bits Available | ||

* V Bits 20 / 40 / 60 degree | * V Bits 20 / 40 / 60 degree | ||

| Line 71: | Line 80: | ||

* 3.175mm Ball end double flute bits | * 3.175mm Ball end double flute bits | ||

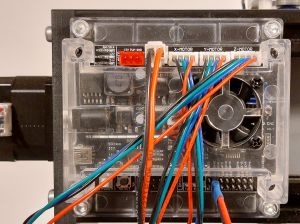

===== Controll Board===== | |||

[[File:CNC 3018 Pro ControlBoard.jpg|thumb|Control board of cnc running GRBL]] | [[File:CNC 3018 Pro ControlBoard.jpg|thumb|Control board of cnc running GRBL]] | ||

* Woodpecker V3.4 Mainboard | |||

* Running GRBL 1.1f | * Running GRBL 1.1f | ||

* Interface Compatibility: Windows, Mac OS, Linux | * Interface Compatibility: Windows, Mac OS, Linux | ||

[Detail comming soon] | [Detail comming soon] | ||

== Ongoing upgrades == | |||

* Chip sucksion | |||

* Emergency Stop around front panel | |||

* New Waste Board | |||

* Different diamenter ER11 Collets holder | |||

== Possible Improvements == | == Possible Improvements == | ||

* Install End Stops | * Install End Stops | ||

| Line 82: | Line 96: | ||

* Better Z – Probe | * Better Z – Probe | ||

* Laser Module for laser cutting / Engraving | * Laser Module for laser cutting / Engraving | ||

* Chip suction device | * Chip suction device | ||

* | * Second better waste Board | ||

* Spindle Upgrade for better cutting | * Spindle Upgrade for better cutting | ||

[Detail comming soon] | [Detail comming soon] | ||

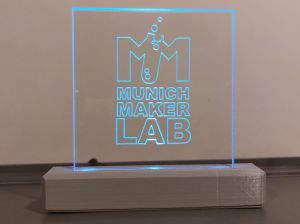

== Sample cuts and demonstration projects == | == Sample cuts and demonstration projects == | ||

| Line 92: | Line 104: | ||

[[File:CNC 3018 Pro PCBTest.jpg|thumb|PCB Trace Test]] | [[File:CNC 3018 Pro PCBTest.jpg|thumb|PCB Trace Test]] | ||

[[File:CNC 3018 Pro EngravingTest.jpg|thumb|Engraving Test of a sticker in lab]] | [[File:CNC 3018 Pro EngravingTest.jpg|thumb|Engraving Test of a sticker in lab]] | ||

==Replacement part list == | |||

== Current GRBL Settings == | == Current GRBL Settings == | ||

<pre> | <pre> | ||

Revision as of 14:35, 12 May 2022

Warning: Beware of the dangers of CNC machines! Use at your own risk and only if you know what exactly you are doing! Please contact Yichen Zhang (Spacezhang) for detailed explaination and tutorial

| CNC 3018 Pro Release status: experimental [box doku] | |

|---|---|

| |

| Description | Milling/ Engraving Machine |

| Author(s) | Yichen Zhang (Spacezhang) |

| Last Version | v0.1 pre alpha test (25.04.2022) |

General Introduction

A small but full-featured cnc running GRBL donated to the lab for use, brought to you and maintained by yichen zhang.

What is the CNC 3018 Pro?

The CNC 3018 Pro is a generic engraving machine. This machine can be used to cut anything from wax to wood and is very good for getting started and learn how to use a CNC machine and how It works.

Acceptable work piece materials

Engrave/ Cut

- MDF / HDF

- Softwood, Hardwood, Plywood

- Acrylic

- PCB

- Very soft Aluminium (no harder than brass or aluminum 6061) (Detail untested)

+ Height Map support

Current Position

[Comming soon]

Getting started

Basic operation

- Change Router bits

- Z Height map

- Change Spindle

[Detail and Tutorial comming soon]

Software Setup & Introduction

Set up the machine -> connect to laptop -> move to origin -> load sample gcode -> start milling

Wood Engraving / Milling

PCB Engraving

Acrylic Engraving / Milling

Test Gcode

[Detail comming soon]

Maintanence

[Detail comming soon]

Material settings

Machine Inventory

Technichal Documentations

Specifications

Mechanical Specifications

- Type: Milling / Engraving machine

- Machine dimensions: 330 x 400 x 240 mm (13.0″ x 15.7″ x 9.4″)

- Working area: 300 x 180 x 45 mm (11.8″ x 7.1″ x 1.8″)

- Frame: Extruded Aluminum

- Linear system: Lead screw driven with rods and linear bearings

- Materials: Woods, Plastics, PVCs, soft aluminum (6061), Nylon, Acrylic, PCBs

- Motion: NEMA 17 Stepper motors

Spindle

- Motor: 775 motor, 24 V , ~8,000 RPM

- Rated current: 1.2A @ 24V.

- Cooling Fan: Internal

- Overall Size: 98x42mm, Full Round Type Ø5mm shaft.

- Collets: ER 11

Routing Bits

- Currently only 3.175 mm (1/8 Inch) Bits Available

- V Bits 20 / 40 / 60 degree

- Multifunctional cutting bits 0.8 – 3.175 mm

- Single flute upward cutting bits 3.175mm, 2mm

- 3.175mm Ball end double flute bits

Controll Board

- Woodpecker V3.4 Mainboard

- Running GRBL 1.1f

- Interface Compatibility: Windows, Mac OS, Linux

[Detail comming soon]

Ongoing upgrades

- Chip sucksion

- Emergency Stop around front panel

- New Waste Board

- Different diamenter ER11 Collets holder

Possible Improvements

- Install End Stops

- Drag Knife cutter for vinyl Logo Cutting

- Better Z – Probe

- Laser Module for laser cutting / Engraving

- Chip suction device

- Second better waste Board

- Spindle Upgrade for better cutting

[Detail comming soon]

Sample cuts and demonstration projects

Replacement part list

Current GRBL Settings

GRBL 1.1f $0=10 $1=25 $2=0 $3=2 $4=0 $5=0 $6=0 $10=1 $11=0.010 $12=0.002 $13=0 $20=0 $21=1 $22=0 $23=0 $24=50.000 $25=500.000 $26=250 $27=1.000 $30=1000 $31=0 $32=0 $100=800.000 $101=800.000 $102=800.000 $110=1000.000 $111=1000.000 $112=800.000 $120=30.000 $121=30.000 $122=30.000 $130=200.000 $131=200.000 $132=200.000