CNC router build: Difference between revisions

SimonRichter (talk | contribs) |

SimonRichter (talk | contribs) (→Handwheel: Now we have a connector.) |

||

| Line 137: | Line 137: | ||

Bought from AliExpress, [[https://www.aliexpress.com/item/Universal-CNC-Router-Hand-Wheel-4-Axis-MPG-Pendant-Handwheel-Emergency-Stop-Siemens-FAGOR-GSK/32652757581.html|product page]] | Bought from AliExpress, [[https://www.aliexpress.com/item/Universal-CNC-Router-Hand-Wheel-4-Axis-MPG-Pendant-Handwheel-Emergency-Stop-Siemens-FAGOR-GSK/32652757581.html|product page]] | ||

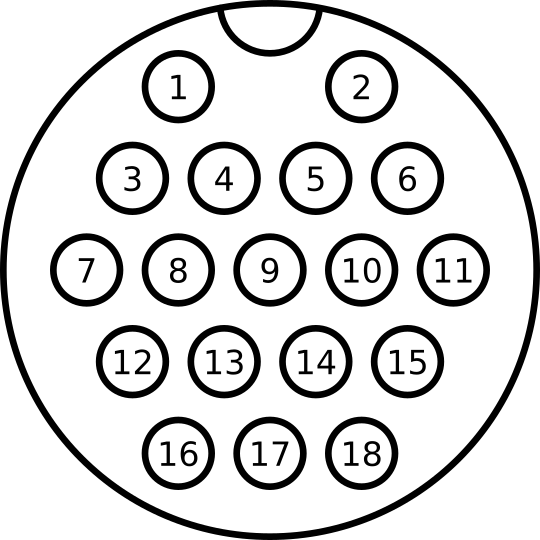

Pinout: [[File:CNC_Handwheel_Pinout. | Pinout: [[File:CNC_Handwheel_Pinout.png]] | ||

1 GND | |||

2 +5V | |||

3 A+ | |||

4 B+ | |||

5 A- | |||

6 B- | |||

7 Emergency Stop (pin 1) | |||

8 Emergency Stop (pin 2) | |||

9 LED+ | |||

10 LED- | |||

11 COM | |||

12 X | |||

13 Y | |||

14 Z | |||

15 4 | |||

16 x1 | |||

17 x10 | |||

18 x100 | |||

==== Encoder Wheel ==== | |||

The wheel needs a +5V power supply, and outputs a slightly lower voltage on A+/B+/A-/B-. One step of the wheel goes through a full cycle. This is not a regular switch, so no connection can be measured. | |||

==== Emergency Stop ==== | |||

This is a simple normally closed switch. | |||

==== LED ==== | |||

A red LED, 20mA standard current drive. | |||

==== Selection Switches ==== | |||

These switches are connected through the "Enable" button on the left. No signal is received unless the button is pressed. | |||

The X, Y, Z and 4 pins are connected to COM when the respective axis is selected, and the enable switch pressed. | |||

The x1, x10 and x100 pins are connected to COM when the respective speed is selected, and the enable switch pressed. | |||

== Controller == | == Controller == | ||

Revision as of 18:08, 21 October 2016

| CNC Mill Release status: experimental [box doku] | |

|---|---|

| Description | |

| Author(s) | Tarwin |

| Last Version | v0.1 |

We want to use the big-ass CNC portal Thomas rescued from the trash to build a CNC router.

Goals

- Mill Aluminium!

- route PCBs

- be open for extensions, easy tool change

Hardware

Motor System

X & Y Motors

Z Motor

- Berger-Lahr VRDM368 50LNBOB

- brake needs 24V to loosen, works.

Motor controllers

- 3x JMC 3M860

Power supplies

- 3x 70V 400W from China

Motor cabeling

Z axis

- 1 = U

- 2 = V

- 3 = W

- 4 = NC

- 5 = break brown cable

- 6 = break white cable

X axis

- 1 = U

- 2 = V

- 3 = W

- 4 = NC

- 5 = NC

- 6 = NC

Endstops

X & Y

- Type unknown

- Seems to be an Solid-state Auto Switch, not just a Reed sensor, same pinout as the SMC

Z

- SMC D-F9H (datasheet) (Solid-state Auto Switch, works like a PNP transistor)

- Omron EE-SX870p Photomicrosensor (datasheet)

Electrical

- all endstops can be driven with 5 to 24V.

- Pinout is: brown: VCC / blue: GND / black: Signal

- Pinout on X: brown: VCC / green: GND / white: Signal

- all have a red led which goes out if they sense something

- Some input here

Endstop RJ45 connector

- - Signal Z-

- - Signal Z+

- - VCC (5-24V) (Brown)

- - Signal Y-

- - GND (Orange)

- - Signal Y+

- - Signal X+

- - Signal X-

List Left Sub D 25 Pol connector

- - 1 Red Cable Driver X

- - 2 Black Cable Driver X

- - 3 Green Cable Driver X

- - 4 Gray Cable Driver X

- - 5 Red Cable Driver Y

- - 6 Black Cable Driver Y

- - 7 Green Cable Driver Y

- - 8 Gray Cable Driver Y

- - 9 Red Cable Driver Z

- - 10 Black Cable Driver Z

- - 11 Green Cable Driver Z

- - 12 Gray Cable Driver Z

- - 13 Free

- - 14 Endstop Blue Cable RJ45=4 -> Signal Y-

- - 15 Endstop Blue/White Cable RJ45=5 -> GND (Orange)

- - 16 Endstop Orange Cable RJ45=2 -> Signal Z+

- - 17 Endstop Orange/White Cable RJ45=1 ->Signal Z-

- - 18 Endstop Green Cable RJ45=6 ->Signal Y+

- - 19 Endstop Green/White Cable RJ45=3 ->VCC (5-24V)(Brown)

- - 20 Endstop Brown Cable RJ45=8 -> Signal X+

- - 21 Endstop Brown/White Cable RJ45=7 -> Signal X-

- - 22 Free

- - 23 Free

- - 24 Free

- - 25 Free

List Right Sub D 25 Pol connector

- - 1 Not Halt Ader 1

- - 2 Not Halt Ader 2

- - 3

- - 4

- - 5

- - 6

- - 7

- - 8

- - 9

- - 10

- - 11

- - 12 Bremse Ader 5

- - 13 Bremse Ader 6

- - 14

- - 15

- - 16

- - 17

- - 18

- - 19

- - 20

- - 21

- - 22

- - 23

- - 24

- - 25

Handwheel

Bought from AliExpress, [page]

1 GND

2 +5V

3 A+

4 B+

5 A-

6 B-

7 Emergency Stop (pin 1)

8 Emergency Stop (pin 2)

9 LED+

10 LED-

11 COM

12 X

13 Y

14 Z

15 4

16 x1

17 x10

18 x100

Encoder Wheel

The wheel needs a +5V power supply, and outputs a slightly lower voltage on A+/B+/A-/B-. One step of the wheel goes through a full cycle. This is not a regular switch, so no connection can be measured.

Emergency Stop

This is a simple normally closed switch.

LED

A red LED, 20mA standard current drive.

Selection Switches

These switches are connected through the "Enable" button on the left. No signal is received unless the button is pressed.

The X, Y, Z and 4 pins are connected to COM when the respective axis is selected, and the enable switch pressed.

The x1, x10 and x100 pins are connected to COM when the respective speed is selected, and the enable switch pressed.

Controller

Software

Sub-projects

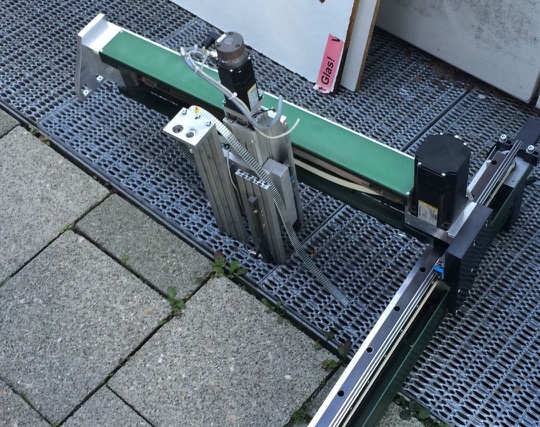

Fix up portal

- The portal needs to put together and fixed up

- Put portal together, replace belt - done

- identifiy / Test endstops - done

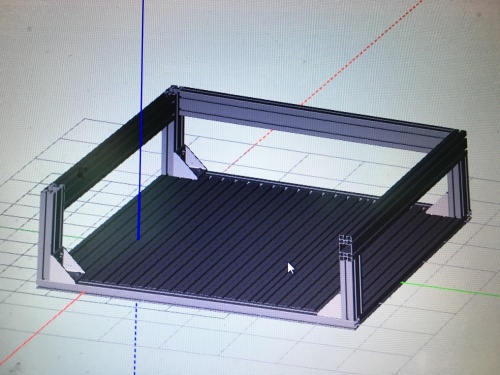

- Build portal frame - in progress (Thomas E)

- Try Z axis brake - done

Frame and table

- The X Axis is raised, the linear bearing runs far above the tool head. This implies a high center of gravity.

- Frame needs to be very stable

- Old workbench?

First draft:

Tool head

- needs to be powerful (Aluminium) and precise (pcbs)

- Find matching Spindle with driver and cooling - done

- Bought this: 2.2kw wassergekühlte Frässpindel

- This can be controlled manually on the inverter or over serial.

- needs its own fuse and a fault current fuse (FI Schutzschalter)

- Technical data:

- 2.2kW / 8,000 - 24,000 RPM

- ER20 spring collets (Spannbuchsen)

- Driver: HY02D223B

- water cooled

Software & Controller

- What will tell the drivers what to do? PC/parallel port, Mikrokontroller, old CNC hardware, ...

- Hardware? What do we need?

- Main page for this: CNC_router_software_eval

Pictures

Last picture of the portal before it ware put apart and brought to the space