CNC3018 Pro: Difference between revisions

No edit summary |

Spacezhang (talk | contribs) (Partially updated explainations and added Fotos) |

||

| Line 1: | Line 1: | ||

<div style="background-color:#FFFFFF; padding: 1.2rem; margin-top: 0.5em; border: 1px solid #c8ccd1; border-top-color:#36C; border-top-width: .4rem; border-radius: .20rem; box-shadow: 2px 2px #F7F8F9;">[[Image:icon-info-96.png|50px]] <big>Warning: This page is still a work in Progress, please contact Yichen Zhang (Spacezhang) on Slack if more Information is needed </big> </div> <noinclude> | <div style="background-color:#FFFFFF; padding: 1.2rem; margin-top: 0.5em; border: 1px solid #c8ccd1; border-top-color:#36C; border-top-width: .4rem; border-radius: .20rem; box-shadow: 2px 2px #F7F8F9;">[[Image:icon-info-96.png|50px]] | ||

<big>Warning: This page is still a work in Progress, please contact Yichen Zhang (Spacezhang) on Slack if more Information is needed </big> </div> <noinclude> | |||

<div style="background-color:#FFFFFF; padding: 1.2rem; margin-top: 0.5em; border: 1px solid #c8ccd1; border-top-color:#FF6347; border-top-width: .4rem; border-radius: .20rem; box-shadow: 2px 2px #F7F8F9;"> | |||

<big>Warning: Beware of the dangers of CNC machines, use only if you know what exactly you are doing or please contact Yichen Zhang (Spacezhang) for detailed explaination and tutorial </big> </div> <noinclude> | |||

{{project | {{project | ||

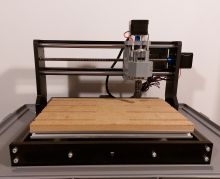

|name = CNC 3018 Pro | |name = CNC 3018 Pro | ||

|description = Milling/ Engraving Machine | |description = Milling/ Engraving Machine | ||

|image = CNC 3018 Pro front.jpg | |||

|author = Yichen Zhang | |author = Yichen Zhang | ||

|username = Spacezhang | |username = Spacezhang | ||

| Line 13: | Line 17: | ||

|status = experimental | |status = experimental | ||

}} | }} | ||

== General Introduction == | == General Introduction == | ||

CNC 3018 PRO ENGRAVER | CNC 3018 PRO ENGRAVER | ||

[[File:CNC 3018 Pro Side.jpg|thumb|Side View]] | |||

=== WHAT IS CNC 3018 PRO? === | === WHAT IS CNC 3018 PRO? === | ||

The CNC 3018 Pro is a generic engraving machine. This machine can be used to cut anything from wax to wood and is very good for getting started and learn how to use a CNC machine and how It works. | The CNC 3018 Pro is a generic engraving machine. This machine can be used to cut anything from wax to wood and is very good for getting started and learn how to use a CNC machine and how It works. | ||

WHAT CAN IT DO? | ===== WHAT CAN IT DO? ===== | ||

Engrave / Cut: PCB/ Wood/ Acrylic/ Very soft Aluminium (no harder than brass or aluminum 6061) + Height Map support | Engrave / Cut: PCB/ Wood/ Acrylic/ Very soft Aluminium (no harder than brass or aluminum 6061) + Height Map support | ||

=== Current Position=== | |||

[Comming soon] | |||

== Getting started == | |||

'''Basic operation''' | '''Basic operation''' | ||

* Change Router bits | * Change Router bits | ||

* Z Height map | * Z Height map | ||

* Change Spindle | * Change Spindle | ||

[Detail and Tutorial comming soon] | |||

=== Software Setup & Introduction === | |||

'''Set up the machine -> connect to laptop -> move to origin -> load sample gcode -> start milling ''' | '''Set up the machine -> connect to laptop -> move to origin -> load sample gcode -> start milling ''' | ||

'''Wood Engraving / Milling ''' | '''Wood Engraving / Milling ''' | ||

'''Software Download ''' | |||

'''PCB Engraving ''' | '''PCB Engraving ''' | ||

'''Acrylic Engraving / Milling ''' | '''Acrylic Engraving / Milling ''' | ||

''' | '''Test Gcode''' | ||

[Detail comming soon] | |||

== Specifications == | == Specifications == | ||

| Line 61: | Line 72: | ||

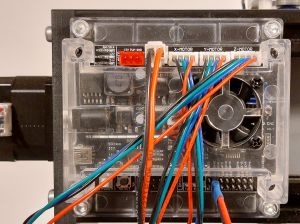

'''CONTROLL BOARD''' | '''CONTROLL BOARD''' | ||

[[File:CNC 3018 Pro ControlBoard.jpg|thumb|Control board of cnc running GRBL]] | |||

* Running GRBL 1.1f | * Running GRBL 1.1f | ||

* Interface Compatibility: Windows, Mac OS, Linux | * Interface Compatibility: Windows, Mac OS, Linux | ||

[Detail comming soon] | |||

== Possible Improvements == | == Possible Improvements == | ||

| Line 74: | Line 87: | ||

* Spindle Upgrade for better cutting | * Spindle Upgrade for better cutting | ||

* Different diamenter ER11 Collets holder | * Different diamenter ER11 Collets holder | ||

[Detail comming soon] | |||

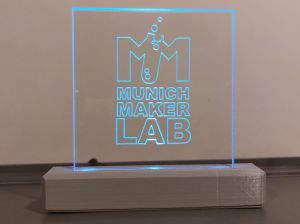

== Sample cuts and demonstration projects == | |||

[[File:20220511 000341.jpg|thumb|MuMaLab Acrylic Cut]] | |||

[[File:CNC 3018 Pro PCBTest.jpg|thumb|PCB Trace Test]] | |||

[[File:CNC 3018 Pro EngravingTest.jpg|thumb|Engraving Test of a sticker in lab]] | |||

== Current GRBL Settings == | == Current GRBL Settings == | ||

<pre> | <pre> | ||

Revision as of 01:16, 11 May 2022

| CNC 3018 Pro Release status: experimental [box doku] | |

|---|---|

| |

| Description | Milling/ Engraving Machine |

| Author(s) | Yichen Zhang (Spacezhang) |

| Last Version | v0.1 pre alpha test (25.04.2022) |

General Introduction

CNC 3018 PRO ENGRAVER

WHAT IS CNC 3018 PRO?

The CNC 3018 Pro is a generic engraving machine. This machine can be used to cut anything from wax to wood and is very good for getting started and learn how to use a CNC machine and how It works.

WHAT CAN IT DO?

Engrave / Cut: PCB/ Wood/ Acrylic/ Very soft Aluminium (no harder than brass or aluminum 6061) + Height Map support

Current Position

[Comming soon]

Getting started

Basic operation

- Change Router bits

- Z Height map

- Change Spindle

[Detail and Tutorial comming soon]

Software Setup & Introduction

Set up the machine -> connect to laptop -> move to origin -> load sample gcode -> start milling Wood Engraving / Milling Software Download PCB Engraving Acrylic Engraving / Milling Test Gcode [Detail comming soon]

Specifications

MECHANICAL SPECIFICATIONS

- Type: Milling / Engraving machine

- Machine dimensions: 330 x 400 x 240 mm (13.0″ x 15.7″ x 9.4″)

- Working area: 300 x 180 x 45 mm (11.8″ x 7.1″ x 1.8″)

- Frame: Extruded Aluminum

- Linear system: Lead screw driven with rods and linear bearings

- Materials: Woods, Plastics, PVCs, soft aluminum (6061), Nylon, Acrylic, PCBs

- Motion: NEMA 17 Stepper motors

SPINDLE

- Motor: 775 motor, 24 V , ~8,000 RPM

- Rated current: 1.2A @ 24V.

- Cooling Fan: Internal

- Overall Size: 98x42mm, Full Round Type Ø5mm shaft.

- Collets: ER 11 (Currently only 3.175mm 1/8 Inch available)

ROUTING BITS

- Currently only 3.175 mm (1/8 Inch) Bits Available

- V Bits 20 / 40 / 60 degree

- Multifunctional cutting bits 0.8 – 3.175 mm

- Single flute upward cutting bits 3.175mm, 2mm

- 3.175mm Ball end double flute bits

CONTROLL BOARD

- Running GRBL 1.1f

- Interface Compatibility: Windows, Mac OS, Linux

[Detail comming soon]

Possible Improvements

- Install End Stops

- Drag Knife cutter for vinyl Logo Cutting

- Better Z – Probe

- Laser Module for laser cutting / Engraving

- Emergency Stop around front panel

- Chip suction device

- Proper Waste Board

- Spindle Upgrade for better cutting

- Different diamenter ER11 Collets holder

[Detail comming soon]

Sample cuts and demonstration projects

Current GRBL Settings

GRBL 1.1f $0=10 $1=25 $2=0 $3=2 $4=0 $5=0 $6=0 $10=1 $11=0.010 $12=0.002 $13=0 $20=0 $21=1 $22=0 $23=0 $24=50.000 $25=500.000 $26=250 $27=1.000 $30=1000 $31=0 $32=0 $100=800.000 $101=800.000 $102=800.000 $110=1000.000 $111=1000.000 $112=800.000 $120=30.000 $121=30.000 $122=30.000 $130=200.000 $131=200.000 $132=200.000