Bambulab P1S: Difference between revisions

No edit summary |

Spacezhang (talk | contribs) No edit summary |

||

| Line 8: | Line 8: | ||

|financing = Bought from official Vendor (€877) | |financing = Bought from official Vendor (€877) | ||

|buildvolume = 256x 256x 256 mm (11.8 x 11.8 x 15.7 in) | |buildvolume = 256x 256x 256 mm (11.8 x 11.8 x 15.7 in) | ||

|nozzle = 0.4 mm stainless steel | |nozzle = 0.4 mm stainless steel | ||

}} | }} | ||

Two years after the last poll in which the Artillery Sidewinder was selected to bridge the gap, a new series of reliable and fast printers with advanced features has finally arrived. Responding to the demand for a faster, enclosed printer capable of printing materials beyond PLA, we've introduced the Bambulab P1S to the lab. This addition will enable us to complete a wider variety of projects in a shorter time frame. You should be able to finishe your project 2 to 4 times faster. | |||

== Details == | == Details == | ||

A fast corexy- based FDM Printer for 1.75mm Filaments. Integrated with varoius sensors and auto-calibration features. | |||

* Enclosed-body for high-temperature filament printing | |||

* Vibration Compensation & Extrusion Compensation | |||

* Up to 16-color printing with AMS | |||

* Up to 20000 mm/s² acceleration, prints a benchy in 18min | |||

* Built-in camera for remote monitoring and timelapse | |||

* Multi-Color Capable with the 4 Color AMS | |||

* All-Metal Hotend, Direct Drive, Filament Runout Sensor, Filament Cutter. | |||

* Integrated Activated Carbon Filter | |||

* Ideal: PLA, PETG, TPU, PVA, PET, ABS, ASA, Capable: PA, PC | |||

** For Flexible Filamet like TPU please use exteral mount on the back instead of the AMS. | |||

* 100-240 VAC, 50/60 Hz, 1000 W @220 V, 350W@110V | |||

== Quickstart guide== | == Quickstart guide== | ||

The Official Bambulab Wiki has some really nice and extensive documentation | |||

* The [https://wiki.bambulab.com/en/p1/manual/intro-p1p P1 Series Introduction] to the machine itself | |||

* The [https://wiki.bambulab.com/en/x1/manual/intro-ams AMS Introduction] to the AMS Multimaterial System | |||

* The [https://wiki.bambulab.com/en/x1/manual/introduction-to-bambu-studio Bambu Studio Introduction] to the slicer used by the machine. | |||

And here is the manual to the printer: [https://wiki.bambulab.com/en/p1/manual [Link<nowiki>]</nowiki>] | |||

== Machine operation == | == Machine operation == | ||

=== Connecting to the Printer === | === Connecting to the Printer === | ||

Revision as of 16:56, 28 July 2024

| BambuLab P1S + AMS Status: working [box doku] | |

|---|---|

| |

| Description | BambuLab P1S + AMS |

| Owner | MuMaLab |

| Financing | Bought from official Vendor (€877) |

| Build Volume | 256x 256x 256 mm (11.8 x 11.8 x 15.7 in) |

| Nozzle | 0.4 mm stainless steel |

Two years after the last poll in which the Artillery Sidewinder was selected to bridge the gap, a new series of reliable and fast printers with advanced features has finally arrived. Responding to the demand for a faster, enclosed printer capable of printing materials beyond PLA, we've introduced the Bambulab P1S to the lab. This addition will enable us to complete a wider variety of projects in a shorter time frame. You should be able to finishe your project 2 to 4 times faster.

Details

A fast corexy- based FDM Printer for 1.75mm Filaments. Integrated with varoius sensors and auto-calibration features.

- Enclosed-body for high-temperature filament printing

- Vibration Compensation & Extrusion Compensation

- Up to 16-color printing with AMS

- Up to 20000 mm/s² acceleration, prints a benchy in 18min

- Built-in camera for remote monitoring and timelapse

- Multi-Color Capable with the 4 Color AMS

- All-Metal Hotend, Direct Drive, Filament Runout Sensor, Filament Cutter.

- Integrated Activated Carbon Filter

- Ideal: PLA, PETG, TPU, PVA, PET, ABS, ASA, Capable: PA, PC

- For Flexible Filamet like TPU please use exteral mount on the back instead of the AMS.

- 100-240 VAC, 50/60 Hz, 1000 W @220 V, 350W@110V

Quickstart guide

The Official Bambulab Wiki has some really nice and extensive documentation

- The P1 Series Introduction to the machine itself

- The AMS Introduction to the AMS Multimaterial System

- The Bambu Studio Introduction to the slicer used by the machine.

And here is the manual to the printer: [Link]

Machine operation

Connecting to the Printer

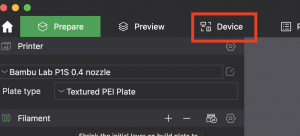

- Go to the printer page in Bambu Studio

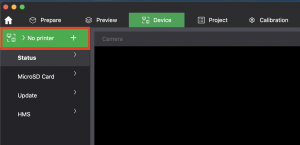

- Click on "No Printer" to open the dropdown

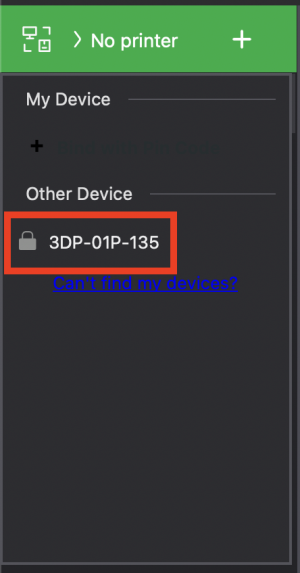

- Select the only printer that shows up

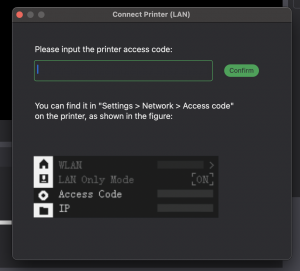

- Enter the access code you can get from the printers settings

And that's it! You should be able to run calibration for your filament, send a print and watch it with the webcam now. Beware that this *should* only work from the munichmakerlab WiFi.

Calibrating your own filament

If you bring non-bambu filament you'll probably have to calibrate it first. For this you'll need the official BambuStudio slicer as calibration does not appear to work with orcaslicer.

To do that you'll have to connect to the printer as described above. After that you'll go over to the calibration tab and run the calibrations listed in there.

Your K Factor (used for pressure advance) should end out at about 0.02 and the flow multiplier at around 0.95.

Insert filament

Check out this page. (The AMS is already set up)

Unload filament

Check link above.

Slicing and Starting the print

Give this video a watch. Make sure to select the P1S in the settings.

Unified bed leveling

[comming soon]

Guide Video

[comming soon]

Suggestions and Feedback

Do you have any suggestions or feedback in regard to the printer, its maintainance and its current status?

Please write your comments below!

- [Comment]