Precious Plastic: Difference between revisions

(Next steps) |

|||

| Line 54: | Line 54: | ||

=== Newsletter === | === Newsletter === | ||

We are working on sending out some updates on what we do once or twice a month. You can [http://eepurl.com/gcZqVf signup here] | We are working on sending out some updates on what we do once or twice a month. You can [http://eepurl.com/gcZqVf signup here] | ||

== Next Steps == | |||

What are our plans for the (very) near future? | |||

* Finish our injection molding machine | |||

* Make some molds and inject some cool parts | |||

* Get a mold for the compression machine | |||

* Have a booth at Make Munich 2019 and show some stuff to the world | |||

* Get our own workshop | |||

== Collecting == | == Collecting == | ||

Revision as of 12:05, 3 January 2019

| Precious Plastic Release status: beta [box doku] | |

|---|---|

| |

| Description | DIY Plastic Recycling |

| Author(s) | David, Katharina, Severin |

Precious Plastic is a project for DIY plastic recycling. David and Severin have started been building a plastic recycling workshop in our lab, and here you can find a bunch of information on it. More about the worldwide project on their website.

Engage

You think this idea is super awesome? You can be a part of it!

Collect Plastic

The easiest way to help out is to collect plastic. Most of us still use a lot of single use plastic at home. Let's put it to some good use.

The Elevator Pitch

Collect these three things:

- Joghurt Cups (also Cream, Custard, .., these plastic things with usually a foil lid on top)

- Shampoo Bottles

- Cream Cheese Containers

Make sure they're clean (you can usually simply throw them in the dishwasher alongside your other dishes), and bring them to our workshop for shredding and recycling.

Get others to collect plastic

- Ask your local Döner place or other restaurant about what they do with plastics. They usually get some of their ingredients in big plastic buckets.

- Get your neighbors involved

Gather Tools and Machine parts

We still need a few things for our workshop. If you or someone you know might have access to any of this, and could donate it to us, that would be amazing. Here's our current list:

- Motors

- Motor for the extrusion machine

- Replacement motor for the shredder

- Electric iron (no need for steam or anything like that)

- T-Shirt Press

- VFD (Variable Frequency Drive) for the extrusion motor

Join our Meetup & our Workshop

We have started our monthly meetup series. Check the Meetup page for the next date.

Donate

Building these machines and keeping them running costs time and money. So does getting them to events and shows. You can send us a donation via PayPal by mentioning Precious Plastic in the message.

PR

Social Media

You can find us on:

Newsletter

We are working on sending out some updates on what we do once or twice a month. You can signup here

Next Steps

What are our plans for the (very) near future?

- Finish our injection molding machine

- Make some molds and inject some cool parts

- Get a mold for the compression machine

- Have a booth at Make Munich 2019 and show some stuff to the world

- Get our own workshop

Collecting

We're collecting different types of plastic in labeled black boxes ( + one box for the stuff we're not sure about). Everything should be clean before it gets into the boxes!

- Acrylic is really hard to recycle apparently, so we're not collecting that

- Sorting through the plastics recycling bin helps us reduce the amount of plastic trash

- Dumpster diving on the KQ?

Processing

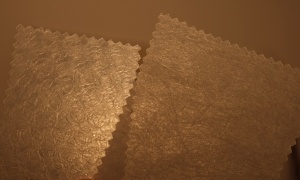

Plastic Bags

Inspired by a video [1] and blogpost [2] of bjornsteinar.

- Material: plastic bags or bubble wrap

- Tools: iron and baking paper

- Steps

- Place material between two sheets of baking paper.

- Iron single sheets as the shrinking is quite drastic and not really predictable (if material ruptures or holes are forming, try reducing the temperature).

- Fuse pre-ironed sheets together to create thicker, stronger material or extend the material dimensions.

- Optionally imprint their textures to the surface by using fabrics or perforated metal plates.

Further research necessary

- Styrofoam

- Disolvable in D-Limonene (Instructable)

Machines

Money spent so far (not really complete)

Shredder

Status: working!

- Hopper is falling apart, needs some glue

- Funnel from shredder into the collection box needs improvement

- Axis of the shredder might be a bit crooked

- More information on motors and how to start them: Drehstromasynchronmotoren, Starten von Motoren

- Electronics: Got a softstarter, missing a direction switch. But that's for later.

Compression

Status:

- Oven finished

- Need to build "Compression unit"

- To be combined with the extrusion machine

Injection

Status:

- Base: done

- Hopper: done.

- Missing the thread on the pipe, then it can be put together.

Other stuff:

- Some premade molds [7]

Extrusion

Status:

- Got the screw and pretty much most other parts

- Hopper already built

- Missing the motor