Precious Plastic: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

m (links to subpages) |

||

| Line 11: | Line 11: | ||

|license = | |license = | ||

}} | }} | ||

'''Precious Plastic''' is a project for DIY plastic recycling. More about the project on [https://preciousplastic.com/ their website] | '''Precious Plastic''' is a project for DIY plastic recycling. More about the project on [https://preciousplastic.com/ their website]. | ||

== Collecting == | == Collecting == | ||

| Line 86: | Line 86: | ||

* Missing the motor | * Missing the motor | ||

== Further pages == | |||

* [[/Cost|Cost]] | |||

* [[/Outreach|Outreach]] | |||

[[Category:Project]] | [[Category:Project]] | ||

Revision as of 07:49, 30 August 2018

| Precious Plastic Release status: experimental [box doku] | |

|---|---|

| Description | DIY Plastic Recycling |

| Author(s) | David, Katharina, Severin |

Precious Plastic is a project for DIY plastic recycling. More about the project on their website.

Collecting

We're collecting different types of plastic in labeled black boxes ( + one box for the stuff we're not sure about). Everything should be clean before it gets into the boxes!

- Acrylic is really hard to recycle apparently, so we're not collecting that

- Sorting through the plastics recycling bin helps us reduce the amount of plastic trash

- Dumpster diving on the KQ?

Processing

Plastic Bags

Inspired by a video [1] and blogpost [2] of bjornsteinar.

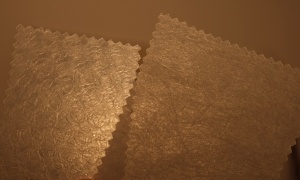

- Material: plastic bags or bubble wrap

- Tools: iron and baking paper

- Steps

- Place material between two sheets of baking paper.

- Iron single sheets as the shrinking is quite drastic and not really predictable (if material ruptures or holes are forming, try reducing the temperature).

- Fuse pre-ironed sheets together to create thicker, stronger material or extend the material dimensions.

- Optionally imprint their textures to the surface by using fabrics or perforated metal plates.

Further research necessary

- Styrofoam

- Disolvable in D-Limonene (Instructable)

Machines

Money spent so far (not really complete)

Shredder

Status: working!

- Hopper is falling apart, needs some glue

- Funnel from shredder into the collection box needs improvement

- Axis of the shredder might be a bit crooked

- More information on motors and how to start them: Drehstromasynchronmotoren, Starten von Motoren

- Electronics: Got a softstarter, missing a direction switch. But that's for later.

Compression

Status:

- Oven finished

- Need to build "Compression unit"

- To be combined with the extrusion machine

Injection

Status:

- Base: done

- Hopper: done.

- Missing the thread on the pipe, then it can be put together.

Other stuff:

- Some premade molds [7]

Extrusion

Status:

- Got the screw and pretty much most other parts

- Hopper already built

- Missing the motor