Precious Plastic: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 49: | Line 49: | ||

** Topics in the forum: [https://davehakkens.nl/community/forums/topic/what-to-do-with-expanded-polystyrene/] [https://davehakkens.nl/community/forums/topic/styrofoam/] | ** Topics in the forum: [https://davehakkens.nl/community/forums/topic/what-to-do-with-expanded-polystyrene/] [https://davehakkens.nl/community/forums/topic/styrofoam/] | ||

** Maybe heat and compression to make it smaller and shreddable? | ** Maybe heat and compression to make it smaller and shreddable? | ||

* Disolvable in D-Limonene ([http://www.instructables.com/id/Recycling-Styrofoam-EPS-Into-Castable-Styrene-Plas/ Instructable]) | |||

** D-Limonene [https://www.3dmensionals.de/kuehling-kuehling-d-limonen-auswaschloesung-u.a.-fuer-hips-1kg] [https://www.3d-druck-material.de/trijexx-d-limonen.html] | |||

== Machines == | == Machines == | ||

| Line 54: | Line 56: | ||

=== Shredder === | === Shredder === | ||

Status: | Status: working! | ||

* | * Hopper is falling apart, needs some glue | ||

* | * Funnel from shredder into the collection box needs improvement | ||

** More information on motors and how to start them: [http://www.swibox.ch/fileadmin/user_upload/elektrokomponenten/Diverse_Grundlagen/Grundlagen_Drehstromasynchronmotoren.pdf Drehstromasynchronmotoren], [http://www.swibox.ch/fileadmin/user_upload/elektrokomponenten/Diverse_Grundlagen/Grundlagen_Starten_von_Motoren.pdf Starten von Motoren] | * Axis of the shredder might be a bit crooked | ||

* More information on motors and how to start them: [http://www.swibox.ch/fileadmin/user_upload/elektrokomponenten/Diverse_Grundlagen/Grundlagen_Drehstromasynchronmotoren.pdf Drehstromasynchronmotoren], [http://www.swibox.ch/fileadmin/user_upload/elektrokomponenten/Diverse_Grundlagen/Grundlagen_Starten_von_Motoren.pdf Starten von Motoren] | |||

* Electronics: Got a softstarter, missing a direction switch. But that's for later. | * Electronics: Got a softstarter, missing a direction switch. But that's for later. | ||

** [https://www.rs-steiner.com/anleitungen/softstarter/eurostart.pdf Manual of the softstarter] | ** [https://www.rs-steiner.com/anleitungen/softstarter/eurostart.pdf Manual of the softstarter] | ||

=== Compression === | === Compression === | ||

| Line 69: | Line 70: | ||

* Need to build "Compression unit" | * Need to build "Compression unit" | ||

** To be combined with the extrusion machine | ** To be combined with the extrusion machine | ||

=== Injection === | === Injection === | ||

Status: | Status: | ||

* Base: | * Base: done | ||

* Hopper: done. | * Hopper: done. | ||

* Missing | * Missing the thread on the pipe, then it can be put together. | ||

* | |||

Other stuff: | |||

* Some premade molds [https://www.techkits.com/collections/molds/] | |||

=== Extrusion === | === Extrusion === | ||

Revision as of 21:50, 14 May 2018

| Precious Plastic Release status: experimental [box doku] | |

|---|---|

| Description | DIY Plastic Recycling |

| Author(s) | David, Katharina, Severin |

Precious Plastic is a project for DIY plastic recycling. More about the project on their website

Collecting

We're collecting different types of plastic in labeled black boxes ( + one box for the stuff we're not sure about). Everything should be clean before it gets into the boxes!

- Acrylic is really hard to recycle apparently, so we're not collecting that

- Sorting through the plastics recycling bin helps us reduce the amount of plastic trash

- Dumpster diving on the KQ?

Processing

Plastic Bags

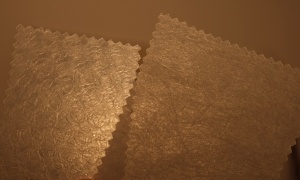

Inspired by a video [1] and blogpost [2] of bjornsteinar.

- Material: plastic bags or bubble wrap

- Tools: iron and baking paper

- Steps

- Place material between two sheets of baking paper.

- Iron single sheets as the shrinking is quite drastic and not really predictable (if material ruptures or holes are forming, try reducing the temperature).

- Fuse pre-ironed sheets together to create thicker, stronger material or extend the material dimensions.

- Optionally imprint their textures to the surface by using fabrics or perforated metal plates.

Further research necessary

- Styrofoam

- Disolvable in D-Limonene (Instructable)

Machines

Money spent so far (not really complete)

Shredder

Status: working!

- Hopper is falling apart, needs some glue

- Funnel from shredder into the collection box needs improvement

- Axis of the shredder might be a bit crooked

- More information on motors and how to start them: Drehstromasynchronmotoren, Starten von Motoren

- Electronics: Got a softstarter, missing a direction switch. But that's for later.

Compression

Status:

- Oven finished

- Need to build "Compression unit"

- To be combined with the extrusion machine

Injection

Status:

- Base: done

- Hopper: done.

- Missing the thread on the pipe, then it can be put together.

Other stuff:

- Some premade molds [7]

Extrusion

Status:

- Got the screw and pretty much most other parts

- Hopper already built

- Missing the motor